The logistics and transportation industry is evolving faster than ever. It’s no longer about simply moving goods from one point to another. Today, success depends on data visibility, automation, and intelligence that connect drivers, warehouses, and customers in real time.

According to Fortune Business Insights, the global logistics software market was valued at USD 15.12 billion in 2024 and is projected to reach USD 27.88 billion by 2032, expanding at a CAGR of 8 percent. This growth proves one thing: logistics companies relying on spreadsheets, disconnected systems, or legacy transportation management tools are losing both efficiency and competitiveness.

For modern logistics enterprises, investing in custom logistics software development has become essential. From route optimization and fleet tracking to warehouse automation and digital proof of delivery, technology now powers every mile, shipment, and customer experience.

This comprehensive guide by Closeloop Technologies explains everything logistics leaders, CTOs, and IT managers should know the types of logistics software, key features, implementation strategies, AI trends, cost structures, and real-world success stories from Closeloop clients such as D2D Global, Grocery Supply Company (GSC), and Autotech Consulting Group (ACG).

Understanding Logistics Software Development

What Is Logistics Software Development?

Logistics software development involves designing, building, and integrating digital solutions that manage and automate every aspect of logistics operations transportation, warehouse management, dispatch, tracking, and analytics.

A custom logistics software development company like Closeloop tailors these platforms around each client’s ecosystem, combining ERP, CRM, IoT, and AI analytics into one unified operational core.

Why It Matters

-

Speed and Accuracy: Automated route mapping, dispatching, and scheduling remove manual errors.

-

Scalability: Cloud-based architecture scales with your fleet, warehouse, and workforce.

-

Visibility: Real-time dashboards and GPS tracking eliminate blind spots.

-

Compliance: Automated audit trails support OEM and government regulations.

Closeloop’s development approach ensures that logistics enterprises gain measurable ROI through automation, visibility, and intelligent data insights.

Key Industry Challenges Driving Digital Transformation

-

Overreliance on Spreadsheets Many mid-sized carriers still rely on Excel for quotes and route planning. D2D Global faced this issue before Closeloop implemented a centralized, cloud-hosted logistics platform that unified dispatch, quoting, and delivery.

-

Fragmented Systems Disconnected quoting, finance, and dispatch tools restrict scalability and create data silos.

-

Lack of Real-Time Visibility Without GPS dashboards, dispatchers operate reactively. Real-time tracking enables proactive management.

-

Complex Compliance OEM documentation, EV handling, and temperature control tracking demand digital precision.

-

Workforce Bottlenecks Manual coordination slows down planning and raises operational costs.

-

Customer Expectations OEMs and customers expect live ETAs, digital proof, and transparent delivery updates.

Closeloop’s D2D Global transformation results:

-

30 percent faster quoting cycles

-

25 percent more accurate cost modeling

-

40 percent reduction in planning effort

These results demonstrate why modernization is now a necessity, not an option.

Types of Logistics Software Solutions

|

Category |

Purpose |

Example / Closeloop Case |

|

Transportation Management System (TMS) |

Automates load planning, carrier selection, and route optimization. |

Closeloop built “D2DLoop” for D2D Global, enabling predictive routing and cost modeling for finished-vehicle transport. |

|

Warehouse Management System (WMS) |

Oversees inventory, picking, storage, and shipment synchronization. |

Closeloop integrated GSC’s ERP with custom WMS modules to align inventory with delivery schedules. |

|

Fleet Management Software |

Tracks vehicle status, driver logs, and maintenance using IoT sensors. |

D2D Global’s IoT-enabled fleet dashboards improved uptime and maintenance forecasting. |

|

Yard Management System (YMS) |

Manages vehicle intake, yard flow, and dispatch readiness. |

ACG’s “AutoTrace” platform digitized multi-yard operations, improving throughput and OEM visibility. |

|

Proof of Delivery (POD) App |

Digitally captures delivery proof through barcode, photo, or signature. |

Closeloop’s Flutter-based POD app for GSC replaced paper workflows and reduced delivery times by 60 percent. |

|

Order & Inventory Management |

Syncs sales orders, stock levels, and fulfillment data across locations. |

Closeloop created APIs for real-time SKU-level tracking for multi-location warehouses. |

|

AI and Predictive Analytics Platform |

Forecasts demand, predicts routes, and optimizes costs. |

D2D Global’s AI modules deliver predictive route planning and cost-efficiency forecasts. |

Closeloop’s portfolio shows how custom logistics solutions enable modular scalability, robust security, and real-time insight.

Core Features of Modern Logistics Software

-

Centralized Cloud Database All operational data stored securely in the cloud for multi-user access with AWS-grade protection.

-

Automated Quoting and Cost Engine Calculates dynamic rates based on fuel, tolls, labor, and distance, eliminating manual errors. Example: D2D Global’s platform reduced quote preparation time by 30 percent.

-

Route Optimization Engine AI algorithms calculate least-cost, least-time routes, considering live traffic, weather, and fuel data.

-

Real-Time Tracking GPS and IoT devices enable end-to-end shipment visibility, improving accuracy and customer satisfaction.

-

Digital Proof of Delivery (POD) Features include barcode scanning, photo capture, and geotagged signatures. GSC achieved full paper elimination through Closeloop’s POD solution.

-

Compliance Workflows Automates audit trails for OEM reporting, EV battery handling, and temperature monitoring.

-

Dashboards and Analytics Role-based KPI dashboards monitor cost variance, on-time delivery rates, and driver performance.

-

Integration Layer Connects ERP, TMS, and WMS modules through secure APIs, avoiding data duplication.

-

Scalability and Security Cloud infrastructure with automatic scaling, encryption, MFA, and audit logging ensures reliability and compliance.

These features transform manual tasks into measurable performance

metrics,

making modern software the operational backbone of logistics efficiency.

Also Read : Logistics Software Development Guide: Types, Features, Industry Solutions & Benefits

Custom vs Off-the-Shelf Logistics Software

When businesses look for logistics software, they often face one critical decision: buy or build. Off-the-shelf products provide generic features at lower upfront costs, while custom logistics software aligns perfectly with business workflows and scales over time.

|

Aspect |

Off-the-Shelf |

Custom Solution |

|

Fit to Operations |

Standardized templates |

Tailored to your processes and data structure |

|

Scalability |

Fixed modules |

Modular, expandable, and adaptable |

|

Integration |

Limited APIs |

Deep integration with ERP, OEM, IoT, and CRM |

|

User Adoption |

Moderate |

High, since it mirrors existing workflows |

|

Cost Over Time |

Cheaper initially |

Greater ROI in the long term |

|

Maintenance |

Vendor-controlled |

Fully owned and flexible updates |

Real-World Example

Grocery Supply Company (GSC) initially used a third-party POD system but faced frequent offline failures and low driver adoption. Closeloop developed a custom Flutter-based mobile app with offline caching and real-time synchronization. The result:

-

100 percent paper elimination

-

60 percent faster deliveries

-

Improved driver compliance and customer feedback scores

Similarly, Autotech Consulting Group (ACG) replaced fragmented legacy tools with AutoTrace, a Closeloop-built yard management system integrated through EDI with OEMs like General Motors. AutoTrace reduced manual data entry by 95 percent and ensured full audit readiness.

Bottom line: Off-the-shelf solutions save short-term cost, but developing a custom software saves your business long-term by improving efficiency, compliance, and scalability.

The Role of Artificial Intelligence and Automation in Logistics

Artificial Intelligence (AI) and automation have become core differentiators for next-generation logistics software. According to McKinsey & Company, integrating AI into logistics processes can reduce forecasting errors by 30 to 50 percent and cut lost sales by up to 65 percent.

How Closeloop Uses AI in Logistics Software

-

Predictive Route Planning AI learns traffic and weather patterns to recommend optimal dispatch routes. D2D Global’s system uses predictive algorithms to minimize idle mileage and fuel usage.

-

Cost Forecasting Models Machine-learning models simulate margin changes under varying labor, toll, and fuel rates.

-

Predictive Maintenance IoT and ML models analyze sensor data to predict vehicle downtime before breakdowns occur.

-

Generative AI Reports The system automatically summarizes route performance, compliance insights, and maintenance anomalies into daily briefings for managers.

-

Voice-Enabled Smart Assistants Dispatchers and drivers use voice commands for scheduling, status updates, and compliance checks.

-

Automated Auditing AI validates delivery photos, digital signatures, and inspection reports for quality and compliance.

AI doesn’t replace dispatchers or planners; it enhances decision-making,

speeds up processes, and provides visibility across complex logistics

networks.

Read Now : AI Innovations in Logistics and Transportation for 2025

Cost of Logistics Software Development

The cost of developing logistics software varies according to complexity, integrations, and technology stack. Based on Closeloop’s project data, here are realistic price ranges:

|

Solution Type |

Estimated Cost Range (USD) |

|

Basic Delivery Tracking / POD App |

35k – 70k |

|

Fleet Management Platform |

80k – 150k |

|

Full Transportation Management System (TMS) |

120k – 250k |

|

Custom Yard Management System (YMS) |

100k – 220k |

|

Enterprise AI-Powered Logistics Platform |

180k – 350k+ |

Primary Cost Drivers

-

Number and scope of modules (TMS, WMS, POD, etc.)

-

Required integrations (ERP, OEM EDI, IoT GPS systems)

-

AI and automation features

-

Platform coverage (web, mobile, cloud)

-

Security and compliance complexity

Measurable ROI

Closeloop clients typically report:

-

30 to 40 percent shorter dispatch cycles

-

25 percent higher quote accuracy

-

70 percent reduction in email dependency

These productivity gains usually offset the initial investment within 12 to 18 months.

Benefits of Investing in Logistics Software

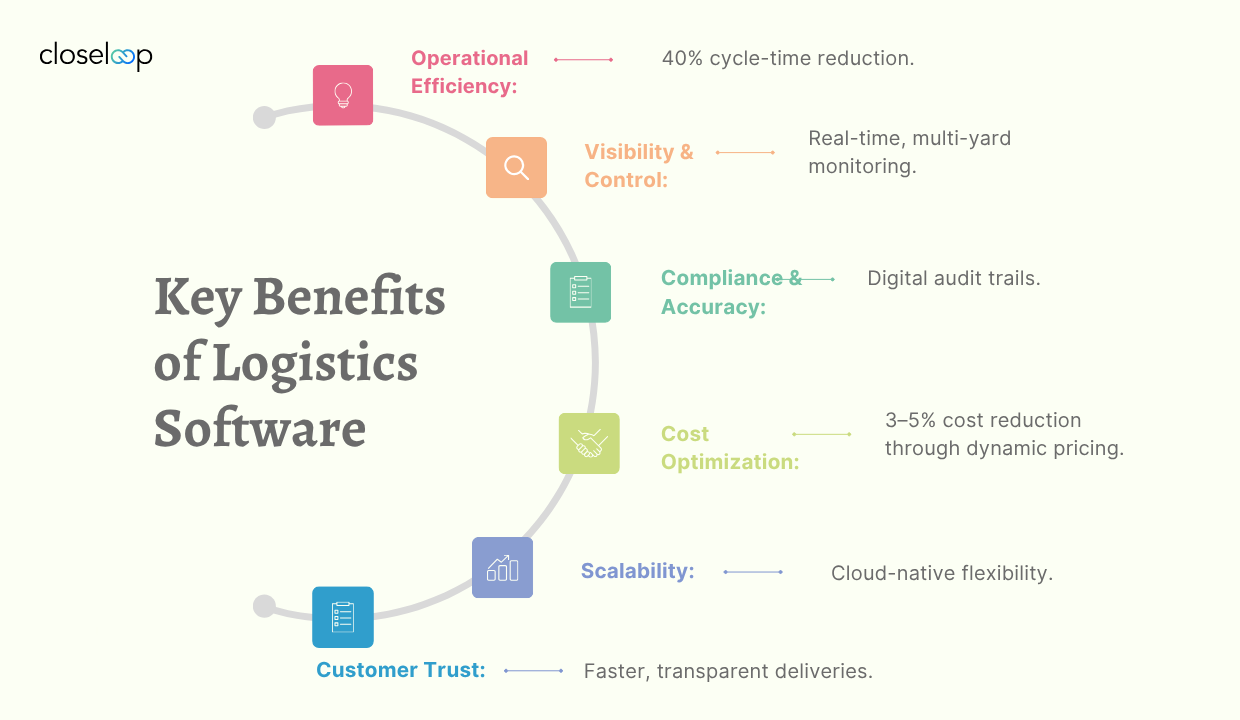

-

Operational Efficiency Automated workflows reduce manual coordination and cut operational cycles by up to 40 percent.

-

Visibility and Control Real-time dashboards offer centralized visibility across multi-yard or multi-state networks.

-

Compliance and Accountability Digital proofs, audit trails, and geotagged delivery data ensure full traceability.

-

Cost Optimization Dynamic cost models prevent margin leaks of 3 to 5 percent, as demonstrated by D2D Global’s results.

-

Scalability and Flexibility Cloud-native architecture expands effortlessly as fleet size or warehouse footprint grows.

-

Customer Experience Transparent tracking and timely deliveries build OEM and dealer trust, improving satisfaction scores.

Closeloop’s ACG AutoTrace deployment improved OEM transparency, reduced

disputes, and accelerated billing cycles proving that smart logistics software

strengthens both operations and relationships.

Industry-Specific Logistics Software Solutions

Closeloop’s logistics software portfolio spans several industries, with each solution tailored to its unique operational challenges.

Automotive Logistics (D2D Global & ACG)

-

Real-time vehicle lifecycle tracking with VIN management

-

AI-assisted compliance workflows for BEV and hybrid vehicles

-

Integration with OEM EDI systems for transparent reporting

Grocery and Retail Distribution (GSC)

-

Offline-first Proof of Delivery ensures continuity even in low-network areas

-

Real-time synchronization between warehouse inventory and delivery fleet

-

Structured returns and asset tracking reduce loss and shrinkage

Fleet and Haul-Away Operations

-

IoT-based telematics modules for preventive maintenance and fuel monitoring

-

Route analytics that optimize daily load distribution

Cold Chain and Perishables

-

Temperature sensor integrations with automated alerts

-

Real-time compliance dashboards to meet food-safety and pharmaceutical standards

OEM Collaboration and EDI Integration

-

Two-way electronic data exchange (EDI) for transparent collaboration

-

Automated invoice generation and payment reconciliation

This level of vertical customization is what differentiates Closeloop

Technologies as a custom logistics software development company that focuses

on measurable, industry-specific outcomes.

Read Now: Cost Breakdown to Build a Custom Logistics Software: Complete Guide

Choosing the Right Logistics Software Development Partner

Selecting the right partner can determine the success of your digital transformation journey. Here are essential factors to consider when choosing a logistics software development company:

-

Domain Expertise Look for a company with proven experience in building TMS, WMS, YMS, and fleet management systems.

-

Customization Capability Your software should align with your unique processes, not the other way around.

-

Integration Skills Ensure the provider has strong experience integrating ERP, EDI, and IoT protocols.

-

Security Standards Verify compliance with SSL/TLS encryption, multi-factor authentication, and GDPR or equivalent standards.

-

Scalable Architecture Cloud-first, API-driven frameworks support future expansion.

-

Ongoing Support and Maintenance Continuous monitoring, upgrades, and proactive issue resolution are essential for long-term success.

Why Choose Closeloop

-

Over 250 projects successfully delivered across logistics, retail, and technology sectors

-

Deep expertise in AI-powered logistics software development and IoT fleet management

-

Strategic partnerships with AWS and major ERP providers for seamless TMS–WMS integration

-

Proven impact through D2D Global, GSC, and ACG case studies

Choosing Closeloop means partnering with a team that builds software

designed

for adaptability, intelligence, and measurable ROI.

The Future of Logistics Software Development

The next decade of logistics will be driven by data, automation, and sustainability. As global supply chains become increasingly interconnected, emerging technologies are redefining logistics operations.

Key Trends Shaping the Future

-

Digital Twins Real-time digital replicas of logistics networks simulate operations and predict bottlenecks.

-

Blockchain Traceability Immutable, transparent transaction records ensure authenticity for high-value goods.

-

Green Logistics Analytics Carbon-tracking dashboards help companies measure and reduce emissions for ESG compliance.

-

Autonomous Fleet Coordination Integration with advanced driver-assist systems and autonomous vehicles enhances safety and efficiency.

-

Unified Supply Chain Platforms Combining OEMs, carriers, and warehouses under a single data fabric eliminates communication silos.

The future belongs to organizations that combine AI, IoT, and predictive

analytics within a unified logistics ecosystem transforming operations into

intelligent, self-optimizing systems.

Conclusion

Logistics software has evolved from an administrative tool into the strategic nerve center of modern transportation networks. Whether it is a route optimization app, a fleet management platform, or a fully integrated AI logistics suite, digital systems now define efficiency, compliance, and customer satisfaction.

Closeloop’s client stories demonstrate measurable transformation:

-

D2D Global: AI-ready TMS reduced planning effort by 40 percent

-

Grocery Supply Company: Offline-first POD app achieved 100 percent paperless proof and faster deliveries

-

Autotech Consulting Group: AutoTrace YMS cut manual data entry by 95 percent and enhanced OEM collaboration

If you are ready to future-proof your logistics business, partner with Closeloop Technologies, a custom logistics software development company that delivers intelligence, compliance, and scalability in every mile of your operation.

Start the Conversation

We collaborate with companies worldwide to design custom IT solutions, offer cutting-edge technical consultation, and seamlessly integrate business-changing systems.

Get in TouchUnlock the power of AI and Automation for your business with our no-cost workshop.

Join our team of experts to explore the transformative potential of intelligent automation. From understanding the latest trends to designing tailored solutions, our workshop provides personalized consultations, empowering you to drive growth and efficiency.

Go to Workshop DetailsExplore Our Latest Articles

Stay abreast of what’s trending in the world of technology with our well-researched and curated articles

View More InsightsCost Breakdown to Build a Custom Logistics Software: Complete Guide

Global logistics is transforming faster than ever. Real-time visibility, automation, and AI...

From Hurdle to Success: Conquering the Top 5 Cloud Adoption Challenges

Cloud adoption continues to accelerate across enterprises, yet significant barriers persist....

Gen AI for HR: Scaling Impact and Redefining the Workplace

The human resources landscape stands at a critical inflection point. Generative AI in HR has...

The AI Procurement Revolution: Why Generative AI Is Your 2025 Game-Changer

Procurement departments are experiencing their most significant transformation since the...