Picture an operations leader at a mid-size freight and distribution firm. Multiple warehouses feed shipments into diverse transport networks, yet the data is scattered across spreadsheets, legacy software, and disconnected tracking tools. Orders arrive late to customers, delivery schedules shift without warning, and no one can produce an accurate view of inventory or fleet capacity on demand.

This scenario is not rare, and it is the reality for many logistics providers navigating fragmented systems in a fast-moving, high-stakes market. Rising transportation costs, fluctuating fuel prices, and heightened customer expectations mean that even small inefficiencies compound into significant financial losses. The challenge is not the absence of technology, but the lack of an integrated platform capable of unifying warehouse, transportation, procurement, and customer service into a single, governed source of truth.

This is where ERP for logistics companies becomes a decisive advantage. Far from being just another IT upgrade, logistics ERP software acts as a strategic operating system for the business, centralizing data, automating core workflows, and providing real-time visibility into every moving part of the supply chain. With a well-designed logistics ERP, dispatchers can optimize routes based on live conditions, warehouse managers can track inventory down to the pallet, and executives can see accurate cost-to-serve analytics before approving the next shipment.

For logistics firms in regions as varied as North America, Europe, and APAC, the business case is clear: ERP solutions for logistics enable operational efficiency, improve cost control, and strengthen market positioning. It allows leaders to pivot quickly during supply chain disruptions, negotiate better with suppliers, and consistently deliver on time, a critical differentiator in industries where service reliability is often the deciding factor for long-term contracts. In short, this is how ERP helps logistics companies move from firefighting to control.

In this guide, we’ll take a clear, business-critical look at ERP for logistics. You’ll learn which key features of logistics ERP matter most for the industry, from inventory and fleet management to analytics and compliance. We’ll explore the tangible benefits of ERP in logistics and the practical considerations for ERP implementation for logistics, including integration, scalability, and governance. Whether you’re evaluating ERP for the first time or replacing an outdated system, the insights ahead will help you make an informed, ROI-driven decision that aligns technology with business outcomes.

The Business Imperative: Why Logistics Firms Need ERP Now

The logistics sector is in constant motion with complex global supply chains, multi-modal transportation networks, and the demand for faster delivery times becoming the norm. Customers now expect real-time updates, accurate delivery windows, and error-free fulfillment. At the same time, operating costs are being squeezed by volatile fuel prices, labor shortages, and regulatory changes across regions.

For leaders in freight forwarding, warehousing, and distribution, this means every operational decision carries more weight, and the margin for error is shrinking.

The Problem with Siloed and Outdated Systems

Despite these pressures, many logistics providers still run on fragmented technology stacks:

-

Warehouse Management Systems (WMS) operating in isolation from transportation planning tools

-

Legacy financial software disconnected from order and inventory data

-

Manual spreadsheets used to reconcile shipments, costs, and schedules

This creates a host of issues:

-

Delayed Decisions – Without real-time information, route and procurement choices are often based on stale data.

-

Inaccurate Data – Discrepancies emerge between inventory records, transit status, and customer-facing updates.

-

Operational Bottlenecks – Manual processes slow down order processing and increase the risk of costly errors.

This results in inefficiencies that directly affect profitability, compliance, and customer trust.

ERP as a Strategic Operating System, Not an IT Upgrade

ERP in transportation and logistics is more than a software replacement. It is an operational backbone designed for accuracy, speed, and scalability. By consolidating warehouse, transportation, procurement, and financial data into a single platform, ERP enables:

-

Timely Data Flow – Real-time updates on shipments, stock levels, and fleet locations

-

Governance and Compliance – Controlled access, audit trails, and region-specific reporting

-

Scalability – Flexible modules that support growth into new geographies or service lines

This unified approach empowers logistics firms to operate with the same precision and agility as their best-in-class competitors. Increasingly, teams choose cloud ERP for logistics to scale quickly while simplifying infrastructure.

|

The ERP market is projected to maintain strong growth, with forecasts indicating it will reach $96 billion by 2032. |

Competitive Advantage in a Global Market

In high-stakes logistics contracts, especially in North America and Europe, service reliability and cost transparency often determine who wins the business. ERP delivers both:

-

Optimized routing to reduce fuel costs

-

Integrated warehouse automation for faster turnaround

-

Analytics that highlight unprofitable routes or customers before they impact margins

The companies that adopt modern ERP software for supply chain management move from reacting to daily disruptions to strategically shaping their operations for growth.

|

Gain clarity on ERP pricing models and learn cost-control strategies every CFO should know before approving investments. |

Core ERP Features Tailored to Logistics Industry

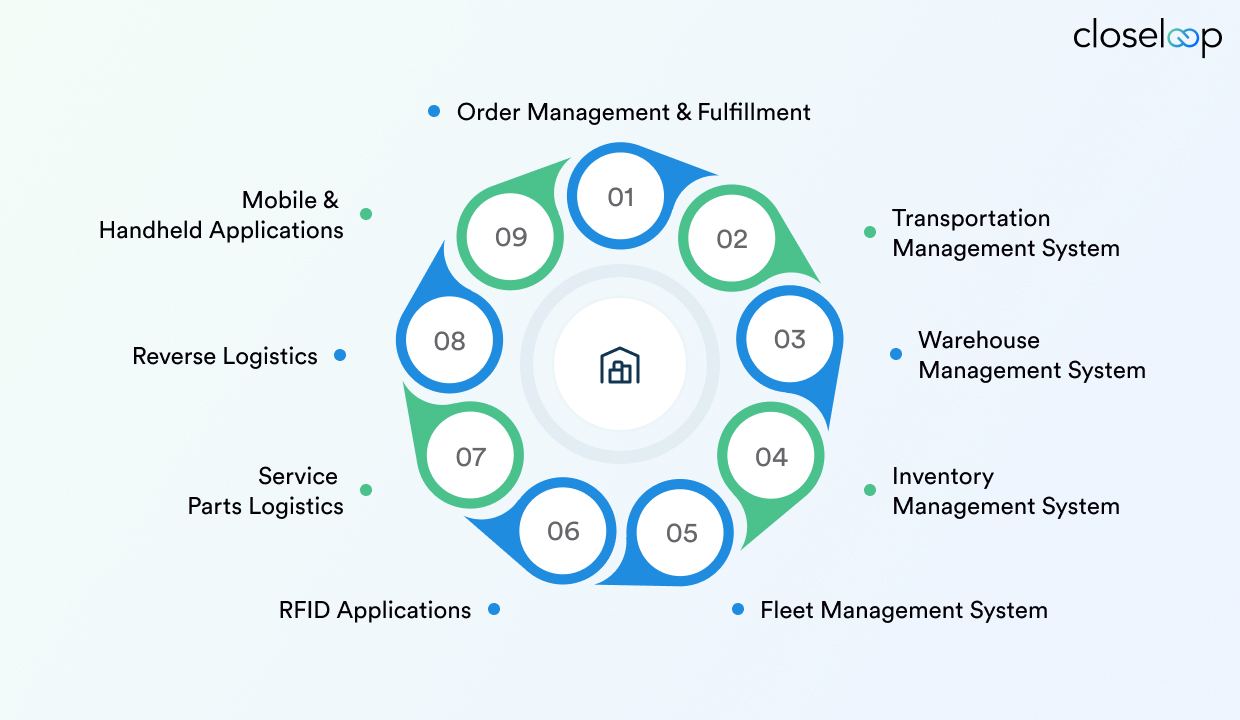

A modern ERP system for logistics is not a monolithic platform; rather, it is a modular, integrated environment that unifies every stage of the operational lifecycle. From inbound supply management to last-mile delivery, targeted ERP modules for logistics operations give leaders the control, visibility, and agility needed in a high-stakes market.

Below are the essential features, each playing a distinct role in driving operational excellence and competitive advantage.

Inventory and Warehouse Management

In logistics, inventory is the foundation for every fulfillment promise made to a customer. ERP centralizes inventory data across all storage locations, including warehouses, depots, and cross-docks, ensuring real-time stock visibility. Advanced functions like lot and batch tracking, bin-level management, and automated picking and packing workflows reduce human error and improve throughput. Together, this forms ERP for fleet and warehouse management where storage, movement, and labor are orchestrated from one source of truth.

Centralized warehouse management reduces excess inventory costs, optimizes space usage, and enables on-time shipment performance, key metrics for maintaining service-level agreements (SLAs) in competitive contracts.

Transportation and Fleet Management

Fleet performance and transportation planning directly affect both cost and service quality. ERP systems with route optimization, carrier management, load consolidation, and fuel monitoring capabilities enable logistics teams to maximize vehicle utilization while reducing operating expenses, core to ERP for logistics process automation on the road network.

Outcome: Better on-time delivery rates, reduced empty miles, improved driver scheduling, and measurable cost savings across the transport network.

|

Recognize the operational signals that indicate your business is ready to scale with NetSuite’s ERP capabilities. |

Order Processing and Customer Integration

Order management is often where customer satisfaction is won or lost. ERP unifies order capture across e-commerce platforms, EDI connections, and customer service teams into one streamlined workflow. Orders flow directly into fulfillment and invoicing, while customers receive automatic updates via integrated portals or notifications.

Business payoff: Faster fulfillment cycles, fewer exceptions, improved order accuracy, and stronger client retention through consistent, transparent communication.

Supplier and Procurement Visibility

ERP brings procurement out of the shadows by consolidating supplier data, purchase orders, and performance metrics. Features like automated reordering, vendor scorecards, and purchase order tracking ensure that supplier relationships are data-driven and performance-focused.

Impact: Better supplier performance, lower material and service costs, and improved supply chain resilience during disruptions.

AI, Analytics and Strategic Insights

ERP dashboards offer demand forecasting, cost-to-serve modeling, and KPI tracking. With AI-powered analytics, these capabilities extend beyond historical analysis, processing large datasets from IoT devices, shipment histories, and market trends to predict demand fluctuations, forecast potential delays, and recommend optimal transport routes. Decision-makers can pivot from reactive firefighting to a proactive strategy, capturing the real benefits of ERP in logistics when analytics are part of daily work.

AI-enhanced insights allow for faster, more accurate planning, optimized resource allocation, and measurable ROI from operational adjustments.

|

Over 65% of organizations now view AI as a critical component of their ERP systems. |

Compliance and Document Management

Cross-border logistics involves a maze of regulations and documentation. ERP platforms offer customs documentation automation, bill of lading generation, export/import compliance tracking, and audit-ready reporting.

Benefit: Compliance is maintained across multiple jurisdictions with less manual effort, mitigating regulatory risks and improving customer trust.

Reverse Logistics and Returns Management

Returns are an unavoidable part of the logistics lifecycle. ERP modules for reverse logistics help coordinate returns pick-ups, manage restocking, and recover reusable materials or packaging.

Outcome: Lower write-off costs, improved recovery of assets, and enhanced customer experience through quick, transparent returns handling.

|

Explore a practical framework for selecting an ERP that aligns with your industry, workflows, and growth goals. |

Integration with IoT and Telematics

The rise of IoT and telematics allows ERP to become a live operational command center. By integrating with temperature sensors, GPS trackers, warehouse robotics, and fleet telematics systems, ERP can automate alerts, trigger workflows, and feed real-time metrics into analytics dashboards.

Advantage: Enhanced asset reliability, proactive issue resolution, reduced wastage, and live operational intelligence for continuous improvement.

These features transform logistics ERP software from a back-office tool into the operational brain of a logistics business, coordinating assets, data, and people in real time to deliver measurable gains in efficiency, service quality, and profitability.

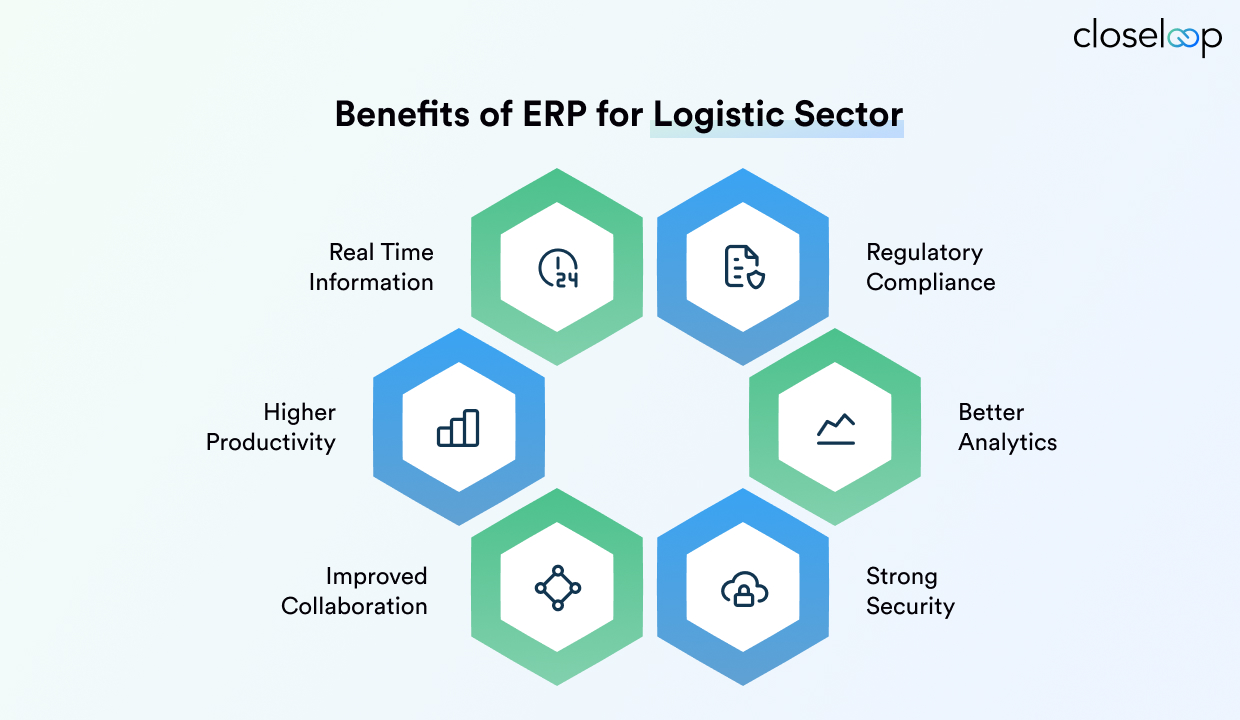

Tangible Benefits for Logistics Leaders

For operations leaders, the value of ERP lies in how directly it impacts margins, service quality, and risk control. These benefits are best understood through four strategic lenses: cost efficiency, agility, data-driven decision-making, and customer loyalty.

Cost Efficiency and Margin Protection

In an industry where operating costs are heavily influenced by variables outside direct control, like fuel prices, global trade tariffs, labor fluctuations, ERP offers the visibility and control needed to protect margins.

-

Inventory Turnover: ERP synchronizes warehouse stock levels with sales and demand forecasts, reducing excess holding costs and freeing up capital. Logistics firms using automated reorder points often see inventory turnover ratios improve by 15–20% within the first year.

-

Transport Cost Control: By consolidating route optimization, load consolidation, and carrier performance data, ERP helps reduce empty miles and unnecessary fuel consumption. Case examples from ERP adopters show transportation costs dropping by 8–12% annually.

-

Headcount Optimization: Automating repetitive tasks, like order entry, invoice generation, and compliance reporting, reduces manual workload. This allows redeployment of staff to higher-value roles rather than increasing headcount as volumes grow.

Cost efficiency achieved through ERP is cumulative. Every optimized route, every avoided overstock, and every hour saved compounds into stronger margins, critical for weathering market volatility without sacrificing service levels.

|

Around 60% of organizations now use ERP systems specifically for supply chain management functions, evidence of how ERP helps logistics companies protect margins. |

Operational Agility

Agility in logistics is the ability to respond to disruptions and market shifts without incurring delays or excess cost. ERP enables this by acting as a single operational command center.

-

Real-Time Response: Integrated fleet tracking and warehouse management allow dispatchers to reroute shipments within minutes of a disruption, whether it’s a port closure or severe weather.

-

Adaptable Workflows: Configurable workflows let operations teams quickly add new carriers, open temporary warehouse capacity, or adjust delivery schedules during seasonal peaks.

-

Scenario Planning: Built-in forecasting tools model the operational impact of changes like a supplier delay, so leaders can pre-empt bottlenecks rather than react after service levels are compromised.

The faster a logistics firm can adjust routes, sourcing strategies, or warehouse operations, the less likely delays will translate into contractual penalties or lost customers. ERP turns agility from a reactive scramble into a proactive strength.

Data-Backed Decisions

In logistics, even small data errors can snowball into expensive problems. ERP provides decision-makers with accurate, governed, and accessible data, removing guesswork from strategic choices. When integrated with AI algorithms, ERP becomes a decision-support engine that detects anomalies in delivery performance, flags emerging risks, and recommends corrective actions before they impact customers.

-

Traceable Audit Trails: Every transaction, such as purchase order, shipment update, and inventory adjustment, is logged with time stamps and user IDs, creating a transparent record for compliance and dispute resolution.

-

Real-Time Dashboards: Executives can view KPIs like on-time delivery percentage, cost per mile, or warehouse throughput without waiting for end-of-month reports. Many buyers now shortlist only the best ERP systems for logistics that include embedded AI.

-

Predictive Forecasting: AI-driven forecasting tools project demand and resource needs with higher accuracy by analyzing both historical and external market data.

Better data, enriched by AI, reduces costly mistakes, accelerates decision-making cycles, and improves confidence in capital allocation.

|

40% of businesses identify AI capabilities as a key factor when evaluating ERP investments, while nearly 16% consider embedded AI functionality a non-negotiable requirement in their ERP software. |

Customer Trust and Retention

In freight and distribution, retaining customers is often more cost-effective than acquiring new ones. ERP strengthens client relationships through accuracy, transparency, and consistent service delivery.

-

Greater Transparency: Customer portals powered by ERP allow clients to track shipments, view delivery timelines, and access order history without manual follow-ups.

-

Fewer Errors: Automated data validation between order capture and fulfillment reduces incorrect shipments, billing discrepancies, and missed delivery windows.

-

Improved Loyalty: Consistent on-time delivery, coupled with proactive communication during disruptions, positions a logistics provider as a dependable long-term partner.

High service reliability lowers churn risk. In industries with multi-year logistics contracts, this directly translates into predictable revenue streams and stronger negotiation leverage during renewals.

From Cost Center to Growth Engine

When measured over time, these benefits shift the perception of logistics ERP from a necessary IT expense to a strategic growth driver. The combination of lower costs, faster operations, data-driven planning, and stronger customer relationships creates a competitive moat. Competitors without these capabilities are forced to compete on price alone, while ERP-enabled firms can compete and win on value, reliability, and speed.

For C-suite leaders, the decision is less about whether ERP will deliver returns and more about how quickly those returns can be realized. In a sector defined by tight margins and high expectations, the businesses that adopt ERP now will be better positioned to lead in both stability and innovation over the next decade.

Practical Implementation Considerations

Selecting and deploying an ERP for a logistics business is not only a technology decision; it is an operational transformation. Treat ERP implementation for logistics as a staged program that anticipates people, process, and platform. Plan for the common challenges in ERP implementation for logistics before kickoff.

The following five guideposts can help ensure your ERP initiative delivers measurable ROI while minimizing disruption to daily operations.

Integration with Existing Systems and Data Migration

Most logistics companies already have a mix of tools in place such as Warehouse Management Systems (WMS), Transportation Management Systems (TMS), accounting software, and customer portals. The value of ERP increases exponentially when these systems are integrated into a single, governed platform.

Integration priorities:

-

Legacy System Harmonization: Identify the core systems that must feed data into ERP from day one, such as fleet tracking software or supplier portals, and plan standardized data interfaces.

-

Data Cleansing: Before data migration, audit and clean existing datasets to remove duplicates, correct inconsistencies, and standardize naming conventions. This step ensures the ERP operates with reliable, decision-ready information from launch.

A well-executed integration allows for uninterrupted visibility across operations, reducing manual reconciliations and ensuring decisions are based on complete, accurate data.

Change Management and User Adoption

The success of an ERP project hinges on people as much as on technology. Even the most advanced system will fail to deliver if employees resist adoption or fail to use key features.

Change management strategies:

-

Training Programs: Provide role-specific training so warehouse teams, dispatchers, and finance staff all understand how ERP simplifies their day-to-day work.

-

Phased Rollout: Introduce modules in stages, such as starting with inventory management before moving to fleet and analytics, to allow teams to adapt without operational overload.

-

Executive Sponsorship: Secure visible leadership support so ERP adoption is framed as a business priority, not just an IT project.

A workforce that understands and trusts the ERP platform is more likely to use it fully, accelerating the realization of efficiency gains and ROI.

|

Understand the complete ERP development process, from planning and customization to integration and long-term optimization. |

Scalability and Flexibility

Logistics operations are rarely static, as new service offerings, acquisitions, and geographic expansion can change system requirements overnight. The ERP platform should be built for scale and AI readiness.

Scalability essentials:

-

Modular Design: Choose an ERP that allows you to add functionality, such as reverse logistics, IoT integration, or advanced analytics, without replacing the entire system.

-

AI-Ready Architecture: Select a platform capable of integrating machine learning models for predictive maintenance, automated document classification, and intelligent resource allocation without costly redevelopment.

-

Configurable Workflows: Ensure workflows can be adapted to match unique operational requirements, such as customs documentation for specific markets or client-specific reporting formats.

As offerings expand or regions change, cloud ERP for logistics helps scale without rebuilding core processes.

Vendor Selection and Ecosystem Compatibility

ERP is a long-term partnership. Selecting the right vendor and ensuring ecosystem compatibility is critical for sustained performance.

Vendor evaluation criteria:

-

Logistics-Focused Expertise: Prioritize vendors with proven deployments in freight, distribution, or 3PL environments.

-

WMS/TMS Compatibility: Confirm native integration options with your existing warehouse and transportation systems to avoid expensive middleware projects.

-

Support Model: Assess the availability of ongoing technical support, upgrade paths, and dedicated account management.

Shortlists often consider both proven suites and ERP software development for logistics when custom modules or unique integrations matter. The right vendor brings both technical and industry knowledge, ensuring that ERP features are not just implemented, but configured to deliver measurable logistics-specific value.

Data Security, Compliance and Governance

ERP platforms consolidate sensitive operational data, including customer records, shipment details, and supplier contracts, making data security and compliance foundational to any implementation.

Security and compliance best practices:

-

Access Controls: Implement role-based permissions to ensure employees see only the data necessary for their role.

-

Audit Logs: Maintain detailed logs of all system changes, transactions, and data access for accountability and compliance audits.

-

Regulatory Alignment: Configure the system to meet industry-specific regulations such as CTPAT (Customs-Trade Partnership Against Terrorism) or GDPR for companies operating in Europe.

Strong governance reduces the risk of data breaches, compliance violations, and reputational damage, while giving clients confidence in the integrity of your operations.

Turning Implementation into a Strategic Advantage

When approached with clear integration plans, active change management, scalability in mind, a well-matched vendor, and strong governance, ERP implementation becomes a competitive advantage. Instead of managing disparate systems, your teams operate from a single, live source of truth. Instead of reacting to operational issues after the fact, you anticipate and address them in real time.

In a sector where speed, precision, and trust determine who wins contracts, the implementation phase is not just about “going live.” It’s about laying the foundation for measurable operational resilience and long-term profitability.

Closeloop: ERP Expertise for the Logistics Sector

At Closeloop, we approach ERP for logistics companies as a strategic architecture project, not just a software deployment. Our engineering-led teams work with freight forwarders, 3PL providers, distributors, and transport operators to design and implement ERP systems that directly address operational pain points, whether it’s fragmented data, inefficient workflows, or lack of real-time visibility.

Our ERP consulting services begin with business-first analysis. We map your current operations, identify integration opportunities with existing systems like WMS, TMS, and IoT-enabled fleet tracking, and define a clear ROI framework before a single line of code is written. This ensures the solution is tailored to your logistics model, not a generic template.

Our ERP services for logistics cover the full lifecycle:

-

ERP Selection and Advisory: Vendor evaluation with a focus on logistics-specific capabilities and ERP modules for logistics operations.

-

Custom ERP software development for logistics: Industry-tuned modules for inventory control, transportation planning, procurement, analytics, and compliance.

-

Integration Services: Seamless data flow between ERP and your operational ecosystem, from warehouse automation systems to supplier portals.

-

Migration and Data Governance: Legacy system harmonization, clean data migration, and governance frameworks to protect sensitive operational information.

-

Ongoing Support and Optimization: Continuous improvement cycles, module enhancements, and KPI-driven performance reviews.

We have helped logistics companies shift from reactive problem-solving to proactive operational control, reducing transportation costs, increasing inventory turnover, and improving on-time delivery rates, evidence that the right ERP solutions for logistics convert strategy into daily results.

When operational clarity and long-term ROI are the priorities, Closeloop delivers ERP solutions designed for growth, resilience, and competitive advantage in the logistics industry.

Strategic Takeaway

For today’s leaders, ERP in transportation and logistics is a long-term operational partner. With AI capabilities now embedded into next-generation ERP, these systems no longer just record what’s happening; they anticipate what will happen, enabling leaders to act with foresight.

High-impact features, such as real-time inventory and fleet management, integrated order processing, supplier visibility, compliance automation, and IoT integration, translate directly into measurable outcomes. Transportation costs decrease as routes are optimized for efficiency, while automated replenishment keeps inventory moving at the right pace. Customers benefit from transparent, accurate updates that build trust, and leadership gains strategic insights from governed, real-time data rather than relying on scattered spreadsheets.

Successful ERP adoption isn’t about rushing to “go live.” It’s about building a resilient operational platform through thoughtful integration, strong change management, scalable architecture, the right vendor partnerships, and a governance-first approach to data. As the future of ERP in logistics industry unfolds, these guardrails ensure ERP evolves with the business, supporting both day-to-day execution and long-term strategic goals.

At Closeloop, we design logistics ERP software with this future in mind, combining deep industry knowledge with engineering-led execution. From vendor selection to post-deployment optimization, our focus is on aligning technology to operational priorities and delivering ROI that compounds over time.

When operational clarity, governable data, and durability matter, reach out for a conversation rooted in ROI. Closeloop’s team is ready to help you define, build, and optimize the ERP platform that becomes a true partner in your logistics leadership journey.

Stay abreast of what's trending in the world of technology

Cost Breakdown to Build a Custom Logistics Software: Complete Guide

Global logistics is transforming faster than ever. Real-time visibility, automation, and AI...

Logistics Software Development Guide: Types, Features, Industry Solutions & Benefits

The logistics and transportation industry is evolving faster than ever. It’s no longer...

From Hurdle to Success: Conquering the Top 5 Cloud Adoption Challenges

Cloud adoption continues to accelerate across enterprises, yet significant barriers persist....

Gen AI for HR: Scaling Impact and Redefining the Workplace

The human resources landscape stands at a critical inflection point. Generative AI in HR has...