For years, AI in transportation and logistics has been talked about more than it has been applied. Pilots ran in silos. Teams experimented with predictive maintenance models or chatbots, adding early signals from conversational AI in logistics and conversational AI for logistics but those experiments rarely scaled across the enterprise. In 2026, that is changing. The conversation has moved from if AI will reshape logistics operations to how companies can deploy it in production with measurable returns.

The timing is not accidental. Supply chains have been under relentless strain. From pandemic disruptions to geopolitical tensions, the industry has learned that efficiency alone is no longer enough and resilience, adaptability, and visibility are now boardroom priorities. Add to that the increasing weight of sustainability mandates, pressure from regulators on emissions reporting, and shifting customer expectations for speed and transparency, and it’s clear why logistics leaders are looking beyond traditional levers. AI is emerging as a system-of-systems that can bring data, operations, and decision-making onto a common plane, anchoring AI for supply chain optimization and the future of AI in logistics.

The economics also favor action. Margins in transport remain razor-thin, and labor shortages continue to drive up costs across trucking, warehousing, and last-mile delivery. Enterprises can’t afford to wait years for incremental improvements. What they want are practical innovations: predictive maintenance that cuts downtime, AI-driven route planning that lowers fuel costs, risk detection that prevents delays before they snowball.

What distinguishes 2026 from earlier waves of experimentation is maturity. Cloud data infrastructure is now standard. Telematics and IoT devices provide a constant stream of operational data. Large language models and generative AI services can be embedded directly into workflows, not just used as standalone copilots with generative AI in transportation and logistics, powering planning, pricing, and customer service. And perhaps most importantly, enterprises are building the governance and compliance frameworks needed to deploy AI responsibly, a non-negotiable when moving billions of dollars of goods across borders, as leaders use AI to reduce compliance risks global logistics.

This blog focuses on that practical layer: the innovations enterprises are adopting now, the ones that show ROI in months rather than years. We’ll explore where AI is having the biggest impact across the logistics value chain, what executives should monitor in AI in logistics, and what to expect in 2026. We’ll also look at the enablers making this possible and the risks leaders must account for.

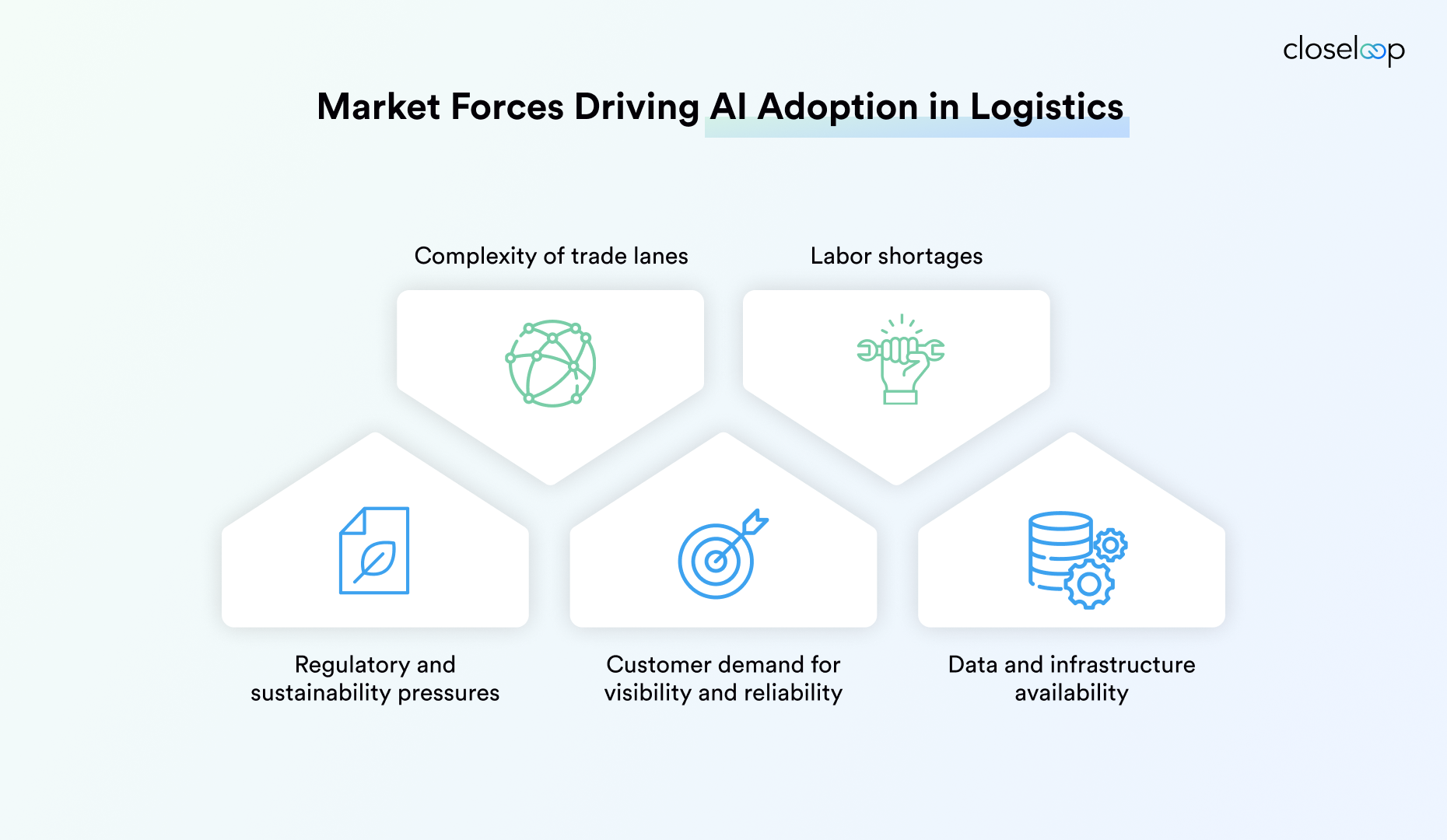

Market Forces Driving AI Adoption in Logistics

Logistics is no longer linear. A single shipment can cross multiple jurisdictions, touch air, sea, rail, and road, and depend on dozens of third-party providers. Trade lanes that once felt stable now shift with geopolitical disruptions, tariffs, and climate-driven route changes.

Traditional planning systems were not designed for this level of volatility. AI is being adopted because it can absorb real-time variables, such as weather, port congestion, customs clearance patterns, and recommend optimal actions faster than human planners or rule-based systems, delivering the benefits of AI in logistics and transportation.

Regulatory and Sustainability Pressures

Sustainability is no longer optional. From the European Union’s emissions trading requirements to California’s stricter trucking standards, regulators are tightening the screws on carbon tracking and environmental disclosures. ESG reporting has moved from an annual checkbox to an operational priority.

Enterprises are under pressure to measure, predict, and actively reduce their environmental footprint. AI is becoming essential here for analyzing fleet performance, simulating fuel consumption, and even forecasting how route choices impact emissions. Compliance automation, driven by AI, is reducing the manual burden of navigating evolving cross-border documentation requirements, as AI in freight and shipping teams standardize reporting across regions.

Labor Shortages and Workforce Cost Dynamics

Driver shortages, warehouse staffing gaps, and rising labor costs are squeezing margins. According to industry reports, the U.S. trucking industry is short by over 80,000 drivers in 2025, directly impacting cost efficiency and delivery reliability, a number expected to rise in coming years. At the same time, wage inflation continues across distribution centers and last-mile delivery.

AI doesn’t replace the workforce outright, but it amplifies productivity by guiding drivers with copilots, automating repetitive warehouse tasks with robotics, and reducing overtime through smarter scheduling, while enabling AI-powered fleet management to balance utilization and safety. For leadership teams, the calculation is simple: without AI, the cost curve keeps climbing.

ALSO READ: Generative AI in Staffing and Recruitment

Increasing Customer Demands for Visibility and Reliability

Customers no longer accept vague delivery windows or opaque shipment updates. Whether it’s a B2B client awaiting critical inventory or an e-commerce buyer tracking a package, expectations are shaped by real-time consumer experiences. Enterprises are under pressure to provide accurate ETAs, proactive delay alerts, and alternate delivery options.

AI supports this by analyzing live traffic, weather, and operational constraints to give customers precise information, using AI for predictive logistics to anticipate exceptions and protect SLAs. Beyond customer satisfaction, this visibility reduces service credits and strengthens contract performance in B2B logistics.

Availability of Data and Modern Computing Infrastructure

Perhaps the most important shift is the data foundation now available to enterprises. Fleets are outfitted with IoT sensors and telematics, warehouses stream operational data from WMS and robotics, and enterprise systems (ERP, CRM, TMS) capture transactions across the value chain. Until recently, much of this data was siloed or too fragmented to be actionable.

The rise of cloud data platforms such as Databricks, Snowflake, and Azure has made it possible to integrate, govern, and feed this data into AI models at scale. Combined with cheaper and more powerful compute, enterprises can now run production-grade AI systems without prohibitive infrastructure costs, enabling real-world AI logistics use cases at enterprise scale.

AI adoption in logistics is a direct response to these market forces. Complexity, compliance, workforce dynamics, customer expectations, and data availability are aligning in 2026 to create a tipping point. Leaders who recognize this alignment are moving quickly from pilots to enterprise-wide deployment.

AI Across the Logistics Value Chain

AI’s value in logistics is not confined to a single function. It touches nearly every stage of the value chain. By 2026, enterprises are no longer asking where AI can help but how far across operations it should extend. Let’s map the key areas where AI is being embedded.

Sourcing and Procurement

AI is improving supplier selection and contract management by analyzing historical performance, pricing volatility, and geopolitical risk. Instead of relying solely on past vendor relationships, procurement teams can use AI to evaluate supplier reliability and predict where disruptions might occur.

This results in smarter sourcing decisions and reduced supply-side risk, with AI in supply chain forecasting informing forward contracts and inventory buffers.

Freight and Fleet Operations

At the heart of logistics is asset utilization. AI-driven predictive maintenance helps fleets avoid costly breakdowns by flagging potential failures before they occur. Freight companies are also applying AI to optimize load planning and capacity allocation, reducing empty miles and improving margins.

For dispatchers and drivers, AI copilots are increasingly common, providing real-time decision support on routing, compliance, and fuel efficiency, and strengthening AI-powered fleet management.

Warehousing and Yard Management

Warehouses are adopting AI to orchestrate robotics for picking and palletizing, while algorithms optimize inventory slotting for faster throughput. In the yard, AI tools manage gate scheduling, dock assignments, and vehicle movements, reducing bottlenecks that ripple into costly delays, marking clear momentum in AI in warehouse automation.

Digital twins of warehouse layouts and yard operations allow managers to simulate changes and test improvements before committing resources.

Route Planning and Last-Mile Delivery

The last mile remains one of the most expensive and complex parts of logistics. AI-driven route optimization uses real-time data, including traffic, weather, and delivery density, to dynamically adjust plans, demonstrating AI in route optimization for fuel and time savings.

Beyond routing, AI predicts delivery windows with higher accuracy, reducing missed deliveries and improving SLA adherence. For urban logistics, AI is supporting micro-fulfillment centers and drone delivery pilots, though these remain early-stage for most enterprises.

ALSO READ: Generative AI in Home Run Financing

Customer Engagement and After-Sales

Customers increasingly expect precise shipment tracking and proactive communication. AI chatbots and virtual assistants handle routine queries, while predictive models anticipate delays and suggest alternate solutions before customers even ask, an extension of conversational AI in logistics.

For enterprise contracts, AI supports more personalized SLAs and dynamic pricing models based on service performance.

Together, these applications form a connected network where data flows across procurement, operations, delivery, and customer touchpoints.

Practical AI Innovations in Logistics and Transportation

AI in logistics has moved from pilot projects to production-grade solutions that generate measurable returns. Below are the core areas where enterprises are deploying AI at scale, highlighting AI in logistics 2026 innovation priorities.

AI in Fleet and Freight Operations

Predictive Maintenance

Fleet downtime remains one of the most expensive risks in logistics. A single unscheduled breakdown can disrupt delivery schedules, trigger penalties, and strain customer relationships. AI-powered predictive maintenance systems analyze sensor data, such as engine vibration, fuel consumption, brake wear, and tire pressure, to anticipate failures before they occur.

According to McKinsey, predictive maintenance can reduce maintenance costs by up to 40% and cut downtime by up to 50%. In 2026, many carriers are standardizing these models across their fleets, treating predictive maintenance as a baseline capability rather than an experimental add-on, a core thread in AI in freight and shipping.

Dynamic Pricing for Freight Capacity Allocation

Traditional freight pricing models often rely on static contracts or manual negotiations. AI introduces dynamic pricing engines that adjust rates based on demand, seasonality, and capacity utilization. This mirrors the airline industry’s revenue management approach but applied to freight.

Large providers like Maersk and DHL are already experimenting with AI-based pricing, allowing them to balance supply and demand more effectively while protecting margins in volatile markets, one of many real-world AI logistics use cases.

AI Copilots for Dispatchers and Drivers

Dispatchers and drivers make hundreds of micro-decisions daily including routing, compliance checks, rest scheduling, and load balancing. AI copilots, powered by natural language interfaces and real-time data integration, provide recommendations in context, serving as generative AI in transportation and logistics assistants for ops teams.

For example, copilots can alert a driver to a low-emission zone ahead and suggest a compliant route. For dispatchers, copilots highlight underutilized assets or flag drivers approaching hours-of-service limits. This human-AI partnership improves both safety and efficiency.

|

According to McKinsey & Company, 92 % of executives plan to increase AI spending in the next three years, with 55 % expecting at least a 10 % uplift. |

Intelligent Route Optimization and Planning

Multimodal Route Planning

AI is reshaping route planning by considering all available modes, road, rail, sea, and air, in a unified model. Instead of treating each mode separately, enterprises can optimize across the network for cost, speed, and sustainability. AI tools evaluate port congestion, rail delays, and airport throughput to recommend the best multimodal mix, aligning to AI in transportation 2026 strategies.

Last-Mile Optimization

Last-mile delivery remains the most expensive portion of logistics, accounting for up to 50% of overall costs. AI-driven optimization models process live traffic, weather, and delivery density to re-route vehicles dynamically. Retailers are combining AI with micro-fulfillment centers, reducing distance to customer and improving delivery reliability, as AI in route optimization matures across dense urban networks.

ALSO READ: Generative AI in Retail

SLA Reliability and Delivery Prediction

Missed service-level agreements (SLAs) can lead to financial penalties and reputational damage. AI models now predict time-windows with much greater accuracy, drawing from historical delivery data and live conditions. UPS, for instance, has applied AI to refine ETA predictions, reducing missed windows and boosting customer satisfaction, illustrating the benefits of AI in logistics and transportation.

Warehouse and Yard Automation

AI-Powered Robotics

Warehouses are adopting AI-driven robotics for picking, packing, and palletizing. Robots equipped with computer vision can identify products, assess packaging needs, and collaborate with humans in hybrid environments. Many distribution centers run fleets of AI-controlled robots, orchestrated by central AI platforms that allocate tasks based on throughput requirements, proof of scaled AI in warehouse automation.

Digital Twins for Space Utilization

A growing number of enterprises are creating digital twins of their warehouses. These AI-powered replicas simulate how layout changes, staffing adjustments, or new equipment would impact performance. Instead of relying on static spreadsheets, managers can run “what-if” scenarios before investing capital. Deloitte notes that digital twins can improve space utilization by up to 20%, a measurable return in AI in logistics.

Yard Management Optimization

AI tools are moving outside the warehouse to manage yards. Algorithms slot vehicles, assign docks, and optimize gate-in/gate-out scheduling. By anticipating congestion and automatically rescheduling where necessary, AI reduces idle times that previously created ripple effects across supply chains, supporting AI-powered fleet management.

ALSO READ: Generative AI in Supply Chain

Supply Chain Visibility and Risk Management

Demand Forecasting and Inventory Positioning

Forecasting has always been central to logistics but demand volatility makes it harder than ever. AI models incorporate real-time market data, seasonality, promotions, and even social sentiment to produce more accurate forecasts. This ensures inventory is positioned closer to demand hubs, reducing carrying costs and improving responsiveness, thanks to AI in supply chain forecasting.

Disruption Detection

Large language models (LLMs) and predictive analytics are now scanning global news, weather alerts, and government advisories to detect disruptions earlier. Strikes, port closures, or natural disasters are flagged in real time, giving supply chain leaders more lead time to adjust routes or sourcing strategies, one of the headline AI logistics trends 2026.

Risk Scoring and Mitigation

AI provides risk scores across suppliers, carriers, and routes. These scores are used to simulate scenarios, what happens if a critical supplier fails, or if a border tightens controls? Rather than reacting after disruptions, enterprises can proactively adjust procurement, reroute shipments, or build buffer capacity, often using an AI agent for predictive cross-border logistics software to coordinate responses.

AI in Customer Experience and Service

Intelligent Chatbots

Shipment queries, delivery rescheduling, and invoice clarifications can consume thousands of hours of customer service time. AI chatbots, now far more sophisticated than earlier generations, handle most of these interactions. They integrate directly with TMS and CRM systems, pulling live shipment data into conversations, as conversational AI for logistics becomes standard in contact centers.

Proactive Alerts

Instead of waiting for customers to complain about delays, AI systems send proactive notifications with revised ETAs or alternate delivery options. This shift, from reactive to proactive service, builds trust and reduces inbound call volumes, showcasing the benefits of AI in logistics and transportation.

Personalized Offerings

For B2B clients, AI enables personalized contract terms, pricing models, and service levels. For example, high-value clients may receive premium SLA guarantees, while others are offered more cost-effective but flexible options. This personalization at scale was previously impossible without AI-driven analytics, and reflects AI applications in logistics 2026.

RELATED READ: Generative AI in Data Analytics

AI for Sustainability and Compliance

Carbon Footprint Optimization

With regulators demanding granular emissions data, AI helps enterprises calculate and reduce their footprint. Models assess how routes, packaging, and vehicle choices affect carbon output. For instance, an AI system can compare emissions between a truckload and rail alternative, enabling greener and often cheaper choices, supporting AI in transportation 2026 decarbonization goals.

Compliance Automation

Cross-border logistics involves mountains of documentation. AI systems are now automating customs declarations, verifying compliance with trade restrictions, and reducing errors that previously led to costly delays. DHL and Maersk are piloting AI-driven customs platforms to accelerate clearance times, as enterprises use AI to reduce compliance risks in global logistics.

Green Fleet Management

Enterprises are transitioning to electric and hybrid fleets, and AI is central to managing them. Algorithms optimize charging schedules, balance EV range limitations, and recommend energy-efficient driving behaviors. As fuel costs rise and sustainability pressures grow, AI-driven fleet management becomes a competitive advantage.

These areas showcase how AI is embedded across operations with measurable impact. From predictive maintenance that saves millions annually to carbon modeling that ensures compliance, logistics leaders in 2026 are moving quickly to capture value.

In the next section, we’ll examine the technology enablers making these innovations possible and the governance considerations that must accompany them.

Technology Enablers Behind the Scenes

The AI use cases shaping logistics in 2026 don’t exist in isolation. They rely on a set of underlying technologies that make them possible. Without these enablers, predictive maintenance, real-time routing, or automated compliance would remain aspirational. Let’s look at the backbone powering AI-driven logistics.

IoT, Telematics, and Real-Time Data Streams

Modern fleets and warehouses are saturated with sensors. Trucks carry telematics units tracking speed, fuel consumption, and component health. Warehouses use RFID tags, scanners, and robotics data to monitor asset movement. Ports and yards deploy cameras and GPS for gate-in/gate-out monitoring.

What makes this data valuable is not just the capture, but the constant stream into AI systems. In predictive maintenance, for example, vibration and temperature readings are processed in real time, allowing models to flag anomalies long before breakdowns. Without IoT and telematics, AI would be operating blind, limiting AI in logistics 2026 outcomes.

Cloud Data Platforms as AI Foundations

Raw sensor and operational data are only useful if enterprises can store, process, and analyze them efficiently. Platforms like Databricks and Snowflake have become central because they unify structured and unstructured logistics data in a governed, scalable environment.

These platforms allow AI models to be trained on historical datasets and deployed against live streams without building bespoke pipelines from scratch. For enterprises, the cloud foundation provides not just scale but governance, ensuring compliance while enabling fast experimentation, accelerating AI innovations in logistics.

ALSO READ: Databricks vs Snowflake - A C-Suite Guide

LLMs and Agent-Based AI for Decision-Making

Large language models (LLMs) and agent frameworks are beginning to move beyond chat interfaces and into operational decision-making. Logistics planners now use LLM-powered copilots that parse natural language queries like, “Show me suppliers at highest risk of delay next quarter” and respond with contextual, data-driven insights.

Agentic AI extends this further: instead of just answering, these systems can trigger workflows, rerouting shipments, adjusting schedules, or drafting compliance documents, maturing generative AI in transportation and logistics from insight to action. For leaders, this shift means fewer manual interventions and more autonomous, closed-loop decision cycles.

Integration with ERP and CRM Systems

AI adds value when it’s embedded into the systems decision-makers already use. In logistics, that means ERP systems (like NetSuite) and CRM systems (like Salesforce) that track financials, contracts, and customer relationships. When AI models connect directly into these environments, the insights flow seamlessly into billing, invoicing, order management, or customer communications.

For example, an AI forecast of delayed shipments can automatically trigger CRM workflows to update customers or adjust SLAs. This integration prevents the disconnect between AI pilots and day-to-day business processes, turning pilots into real-world AI logistics use cases.

APIs and EDI Modernization

Legacy electronic data interchange (EDI) protocols have long been the standard for transmitting shipment and customs data, but they were built for static, point-to-point integration. AI-driven logistics requires more flexible, real-time connectivity. APIs are increasingly replacing or augmenting EDI, enabling faster and more dynamic data exchange across carriers, shippers, and regulators.

Some enterprises are deploying “modern EDI,” cloud-based, API-friendly layers that preserve compliance while opening the door for AI to act on live data streams. This modernization is crucial for global logistics networks where delays in data sharing directly translate into service failures, and for AI logistics automation 2026 programs.

AI in logistics looks sophisticated on the surface, but its effectiveness depends on these enablers: sensor-rich environments, cloud platforms for data orchestration, advanced AI models for decision-making, system integration for workflow continuity, and modern connectivity for speed. Without this backbone, even the most advanced AI models would remain underutilized. With it, logistics enterprises in 2026 can scale AI beyond pilots into enterprise-wide operations.

Risks, Challenges, and Governance Considerations

Adopting AI in logistics is not simply a matter of deploying new software. It introduces new risks, governance requirements, and organizational hurdles. Enterprises that scale responsibly recognize these dimensions as central to success, acknowledging challenges of AI in logistics adoption.

Data Privacy and Security Risks

Transportation data is highly sensitive as it spans customer details, shipment contents, cross-border routes, and financial transactions. A breach doesn’t just expose competitive information; it can compromise safety and regulatory compliance.

AI models require large volumes of this data, often aggregated from multiple systems and partners. Without strong encryption, access controls, and monitoring, enterprises risk creating new attack surfaces. Security frameworks must be built in parallel with AI deployment, not bolted on afterward, to reduce compliance risks in global logistics.

ALSO READ: A Guide to Safe and Compliant AI Adoption

AI Explainability and Regulatory Compliance

As regulators tighten oversight on emissions, customs documentation, and safety standards, enterprises need AI systems that are auditable. Black-box models pose risks when a regulator or client demands to know why a particular shipment was flagged or why a route was chosen.

Explainable AI (XAI) techniques, such as interpretable models, clear audit logs, and decision traceability, are becoming mandatory in logistics operations. Enterprises that can demonstrate not just accuracy but explainability gain an edge in regulatory and contractual negotiations, and in AI in logistics 2026 procurement cycles.

Workforce Adoption and Change Management

AI adoption is as much about people as it is about algorithms. Dispatchers, drivers, and warehouse operators need to trust AI recommendations before they act on them. Poorly executed rollouts risk creating skepticism or outright resistance.

Change management (training programs, human-AI collaboration pilots, and clear communication of benefits) must be prioritized. In many cases, AI copilots work best when introduced as decision support tools rather than replacements, building confidence gradually, easing challenges of AI in logistics adoption.

Cost and ROI Evaluation

AI promises strong returns, but costs can be significant. Building and maintaining data infrastructure, acquiring compute resources, and hiring specialized talent all add up. Leadership teams must evaluate investments against measurable KPIs: downtime reduction, on-time delivery rates, fuel savings, or labor hours saved.

A robust ROI framework helps separate initiatives worth scaling from those better left as pilots. CFOs are increasingly part of the conversation, demanding evidence that AI initiatives align with enterprise cost and resilience strategies, from warehouse robotics to the cost comparison of AI-driven autonomous trucks for logistics.

Vendor Fragmentation vs. Integrated Platforms

The logistics technology ecosystem is crowded. Enterprises face a choice: assemble multiple point solutions from niche vendors or adopt integrated platforms that cover data, AI, and process management in one environment. Fragmentation can lead to integration headaches, inconsistent data pipelines, and higher governance costs.

On the other hand, relying on a single platform may limit flexibility. Leaders are weighing hybrid approaches, standardizing on a core platform (e.g., Databricks, Snowflake) while layering specialized AI applications where differentiation is needed. Vendor strategy is becoming a board-level decision, with implications for cost, scalability, and long-term resilience.

The practical value of AI in logistics is clear, but so are the risks. Enterprises that succeed in 2026 are those that address security, compliance, workforce adoption, cost discipline, and vendor strategy upfront. Treating governance as an enabler, not an afterthought, is what separates pilot projects from enterprise-wide transformation.

The Road Ahead: What to Expect by 2026–2028

Autonomous Trucking and Drones

By the late 2020s, autonomous technologies will begin to move from pilot corridors to commercial deployment. Several U.S. states and parts of Europe are already approving limited autonomous trucking lanes. These systems will initially complement, not replace, drivers, handling long-haul stretches while humans manage complex last-mile delivery.

Drones, too, will shift from small-scale pilots to more routine roles in rural delivery, inventory inspection, and yard monitoring. The common thread is AI, which orchestrates navigation, safety decisions, and fleet scheduling.

AI-Driven Contract and Pricing Negotiations

Freight contracts and service agreements remain negotiation-heavy and time-consuming. Over the next three years, AI will take on a greater role in analyzing historical contract data, benchmarking rates, and even drafting dynamic pricing terms.

For shippers, this means faster negotiations and more transparent cost structures. For carriers, it offers the ability to adjust terms in line with shifting fuel costs, demand surges, or sustainability goals. Natural language models will increasingly serve as copilots for procurement and legal teams, accelerating cycles without replacing oversight, continuing AI innovations in logistics.

Wider Adoption of AI Sustainability Scoring

Regulators and customers alike will expect logistics providers to quantify sustainability with the same rigor as financial metrics. By 2028, AI-driven sustainability scoring will become embedded in RFPs, tenders, and contracts. Carriers that cannot provide accurate carbon reporting may be excluded from major bids.

AI models will standardize emissions calculations across fleets, packaging, and warehousing operations, allowing enterprises to benchmark performance against peers and identify new efficiencies. Sustainability will shift from marketing advantage to procurement prerequisite, a defining theme in the future of AI in logistics.

Industry Consolidation of AI Logistics Platforms

The current market is fragmented, with dozens of vendors offering AI tools for narrow logistics tasks. Between 2026 and 2028, expect consolidation as enterprises push for integrated solutions.

Larger players (cloud platforms, ERP providers, global 3PLs) will absorb niche innovators to create unified AI-driven ecosystems. For buyers, this means fewer integration headaches but also tougher vendor lock-in decisions. Selecting long-term partners will require balancing innovation with stability.

The next three years will not be defined by speculative AI breakthroughs but by practical scaling. Autonomous trucks, AI-driven contracts, sustainability scoring, and platform consolidation all reflect the same reality: logistics leaders want tools that deliver measurable outcomes, not hype. The enterprises that succeed will be those that focus on operational adoption where AI moves from experiment to everyday infrastructure.

Wrapping Up

In 2026, AI in logistics has shifted from optional to operational. The industry is entering a phase where predictive maintenance, intelligent routing, warehouse automation, and real-time risk detection are not differentiators but baseline expectations. Enterprises that delay adoption risk higher costs, slower response times, and reduced competitiveness in increasingly volatile trade networks.

The practical impact of AI is already visible. Fleet operators are extending asset life and cutting downtime. Shippers are providing customers with precise ETAs and proactive alerts. Warehouses are running more efficiently with AI-powered robotics and digital twins. At the same time, sustainability teams are using AI to measure and reduce emissions in ways that satisfy regulators and clients alike. These outcomes point to the same conclusion: AI is delivering measurable value across cost reduction, resilience building, and customer experience, capturing the benefits of AI in logistics and transportation.

For C-suite leaders, the imperative now is to move past scattered pilots and adopt an integrated, ROI-driven approach. That means aligning AI initiatives with enterprise priorities, building governance frameworks that address compliance and trust, and selecting technology partners who can scale solutions across the logistics value chain. Decisions on vendor strategy, platform selection, and workforce adoption need to be made at the board level, with ROI metrics tracked as closely as financial performance.

At Closeloop, we approach this challenge as engineers and consultants, not just technology vendors. Our work with enterprises covers data engineering services, AI integration services, and ERP/CRM connectivity, always with a focus on long-term scalability and measurable returns. We help leaders move from experimentation to maturity, designing AI solutions that fit within existing enterprise architecture while preparing for what’s next: autonomous fleets, AI-driven contracting, and platform consolidation.

The road ahead will reward pragmatism. The organizations that thrive will be those that treat AI not as hype, but as infrastructure, an everyday enabler of better operations, stronger resilience, and higher customer value. For logistics leaders, 2026 is the year to act decisively.

Talk to our consultants about scaling AI across your logistics operations with speed, security, and clear returns.

Stay abreast of what's trending in the world of technology

Cost Breakdown to Build a Custom Logistics Software: Complete Guide

Global logistics is transforming faster than ever. Real-time visibility, automation, and AI...

Logistics Software Development Guide: Types, Features, Industry Solutions & Benefits

The logistics and transportation industry is evolving faster than ever. It’s no longer...

From Hurdle to Success: Conquering the Top 5 Cloud Adoption Challenges

Cloud adoption continues to accelerate across enterprises, yet significant barriers persist....

Gen AI for HR: Scaling Impact and Redefining the Workplace

The human resources landscape stands at a critical inflection point. Generative AI in HR has...