Automotive Yard Logistics Digital Transformation

This case study explores how Autotech Consulting Group (ACG), a leading automotive logistics provider in Mexico, transformed its yard operations through digital innovation.

Autotech Consulting Group (ACG)

Autotech Consulting Group (ACG) is a Mexico-based leader in automotive logistics and yard management, operating multiple yards near major manufacturing hubs and at key port locations. ACG's facilities provide large-scale vehicle storage along with value-added services, including accessorizing, pre-delivery inspections, and maintenance. At the port, specialized operations facilitate seamless import and export flows, integrating domestic distribution with international logistics.

Legacy System and Processes

ACG relied heavily on an outdated application combined with manual, paper-based processes to manage its growing yard operations. This setup created inefficiencies, service gaps, and operational risks.

Manual VIN Tracking

Teams had to check one VIN at a time to see its location or what service was applied, wasting hours and introducing errors.

Multi-Yard Complexity

Each yard operated independently, while multiple OEM vehicles with unique compliance rules coexisted, slowing operations and increasing risk of errors.

Fragmented Lifecycle

Vehicles followed different paths (services, damages, holds, inspections), but without a centralized system, workflows were inconsistent, error-prone, and hard to reconcile.

Inefficient Communication

Without seamless integrations, updates on services, holds, and damages were slow, often leading to approval bottlenecks and strained OEM relationships.

Billing Delays

Manual cost tracking and error-prone logs made invoicing slow and unreliable, causing reconciliation challenges with OEMs.

Manual Excel Reporting

All VIN and service data were managed in Excel, requiring manual report creation with no automated way to track or download information, causing delays and errors.

Unlock Full Case Study

One System. Total Transparency.

ACG partnered with Closeloop Technologies to define clear objectives for a new solution:

100% VIN Visibility

Track all vehicles in real time across yards and lifecycle stages.

Real-Time Updates

Replace manual processes with automated, centralized workflows.

Automate Invoicing

Streamline billing and reduce errors, improving reconciliation with OEMs.

Improve Productivity

Provide an intuitive platform to simplify task management and improve efficiency.

Security & Traceability

Close traceability gaps and improve accountability for all vehicle movements.

Multi-Yard Coordination

Standardize processes and compliance across all locations and OEMs.

User Research & Challenges

Discovery Phase

On-Site Analysis & InterviewsDuring the discovery phase, our team conducted site visits in Mexico, whiteboard sessions, wireframing exercises, daily calls, and close collaboration with the client to finalize the Functional Requirements Document (FRD).

Interviews and on-ground observations with yard managers, staff, and OEMs revealed key pain points: yard workers struggled with unreliable tracking and paper logs, managers lacked real-time visibility, and OEMs faced billing disputes.

Key Challenges

Unifying People, Process, and Tech- Standardizing Multi-Yard Operations: Unifying varied yard procedures without disrupting ongoing work.

- Unreliable GPS Signals: Industrial zones limit GPS accuracy, demanding alternate digital tracking methods.

- Complex OEM Integration: Different data formats, EDI structures, and validation rules required detailed mapping.

- Language Barriers: Cross-border teams faced challenges with alignment and feedback.

- Honeywell Integration: Ensuring smooth integration of SDKs with the Flutter-based mobile app.

From Vision to Execution

Closeloop treated ACG's digital transformation as a complete operational reinvention, combining on-ground insights with modern technology.

Ground-Level Understanding

On-site observations at ACG yards to identify real-world pain points and gather operational insights.

Centralized Platform

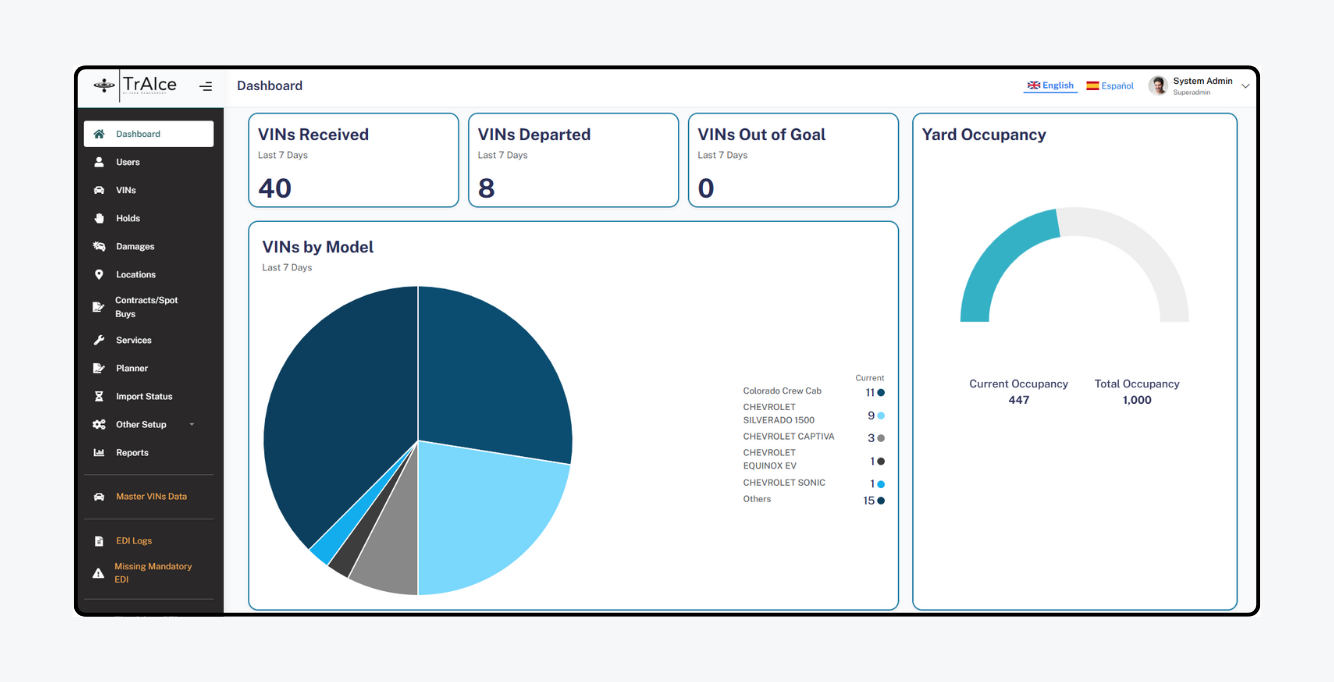

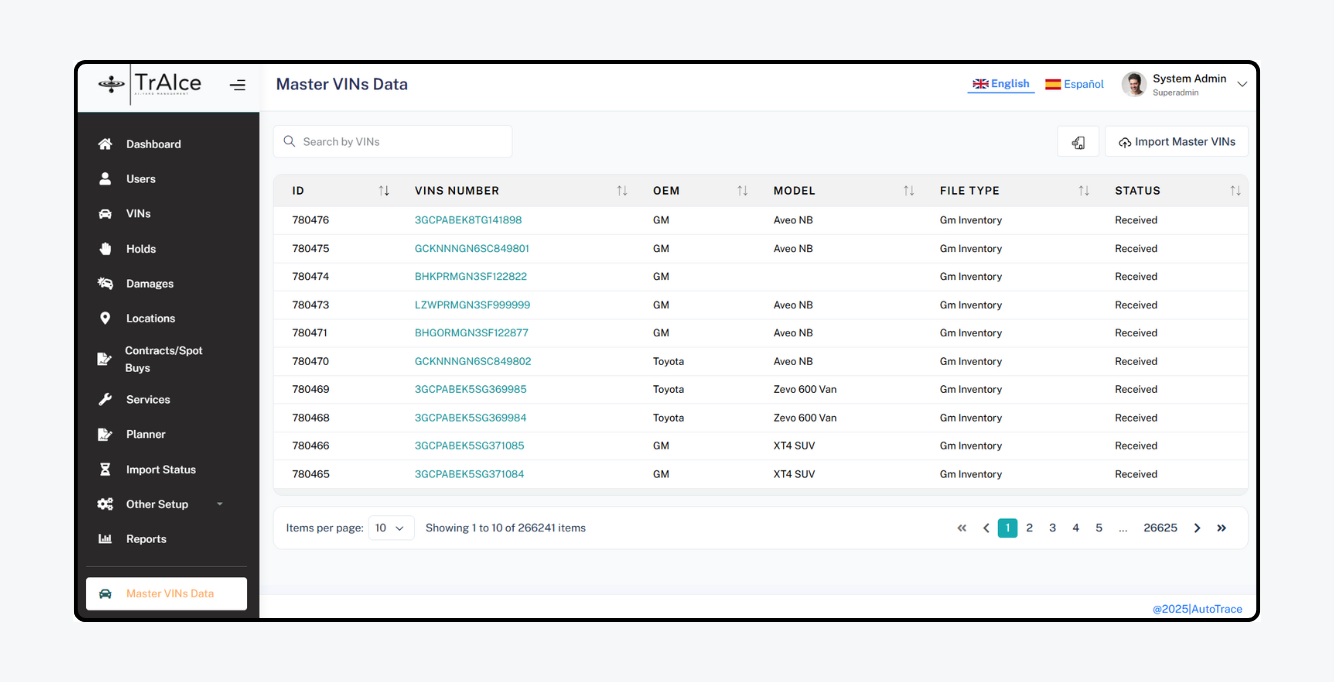

Developed a single dashboard with VIN traceability; migrated cleaned legacy data into a secure centralized database.

Smart Mobile App

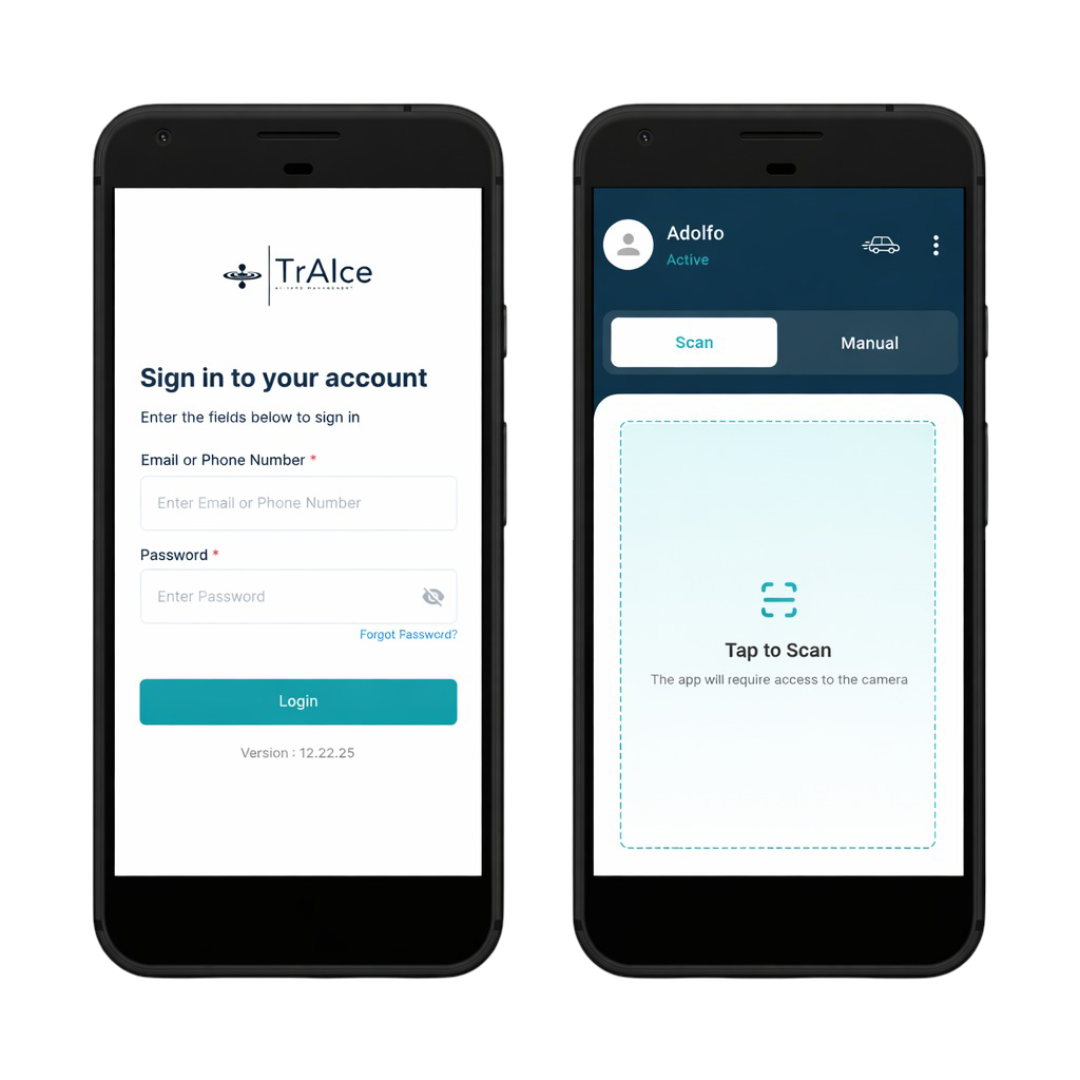

Created a Flutter-based app with Honeywell SDKs for barcode scanning, offline support, and instant sync.

Phased Rollout

Gradual deployment yard by yard, refining features based on feedback and enabling real-time visibility.

A Unified Digital Ecosystem

The solution combined a Honeywell-enabled mobile app with a centralized cloud-based web platform.

Honeywell-Enabled Mobile App

-

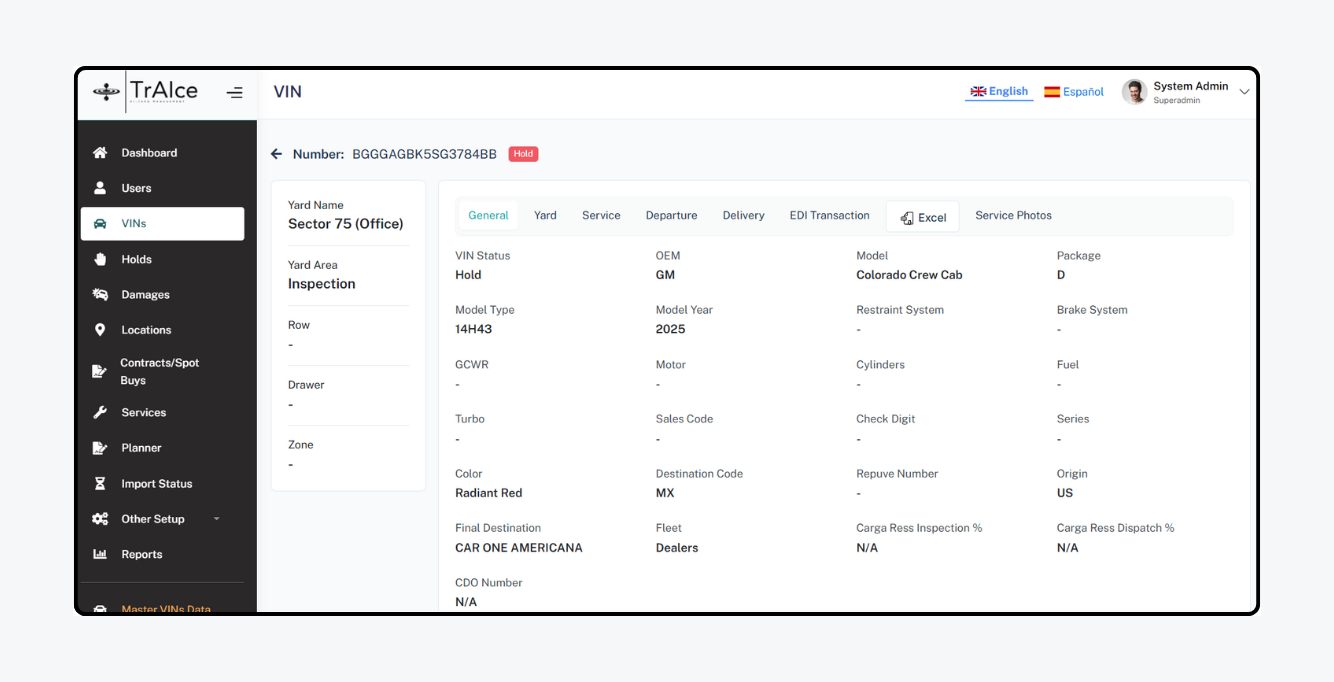

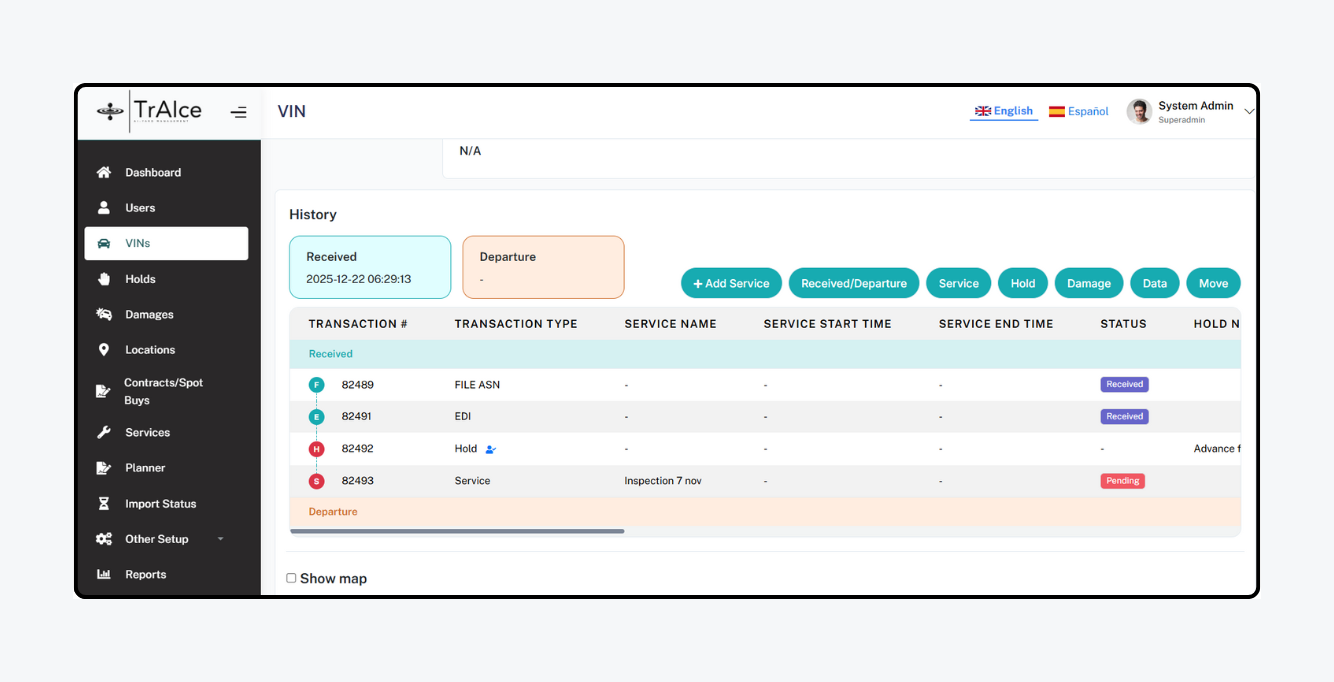

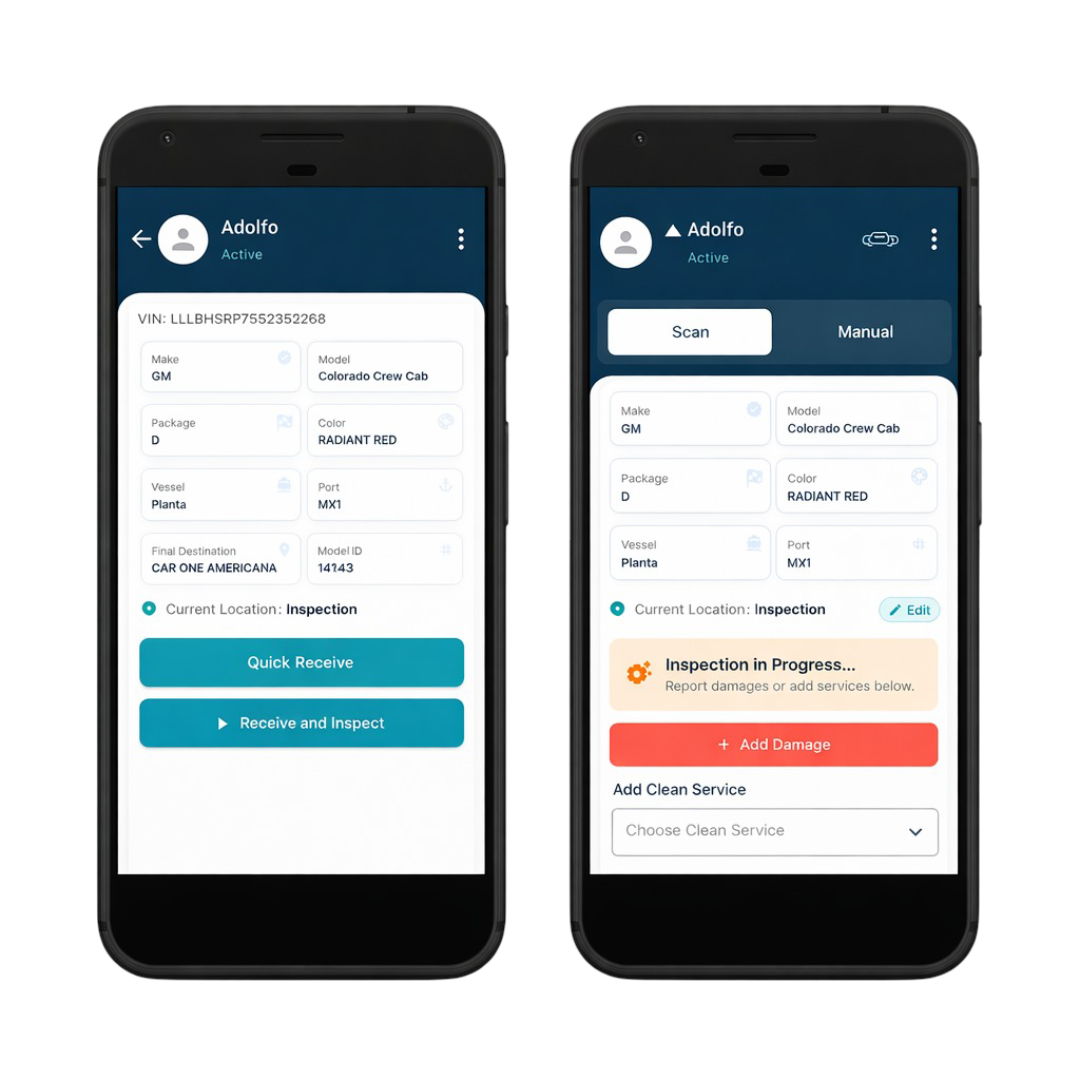

VIN Scanning at Entry Each vehicle is instantly scanned upon arrival, automatically creating a digital record tied to its complete service history.

-

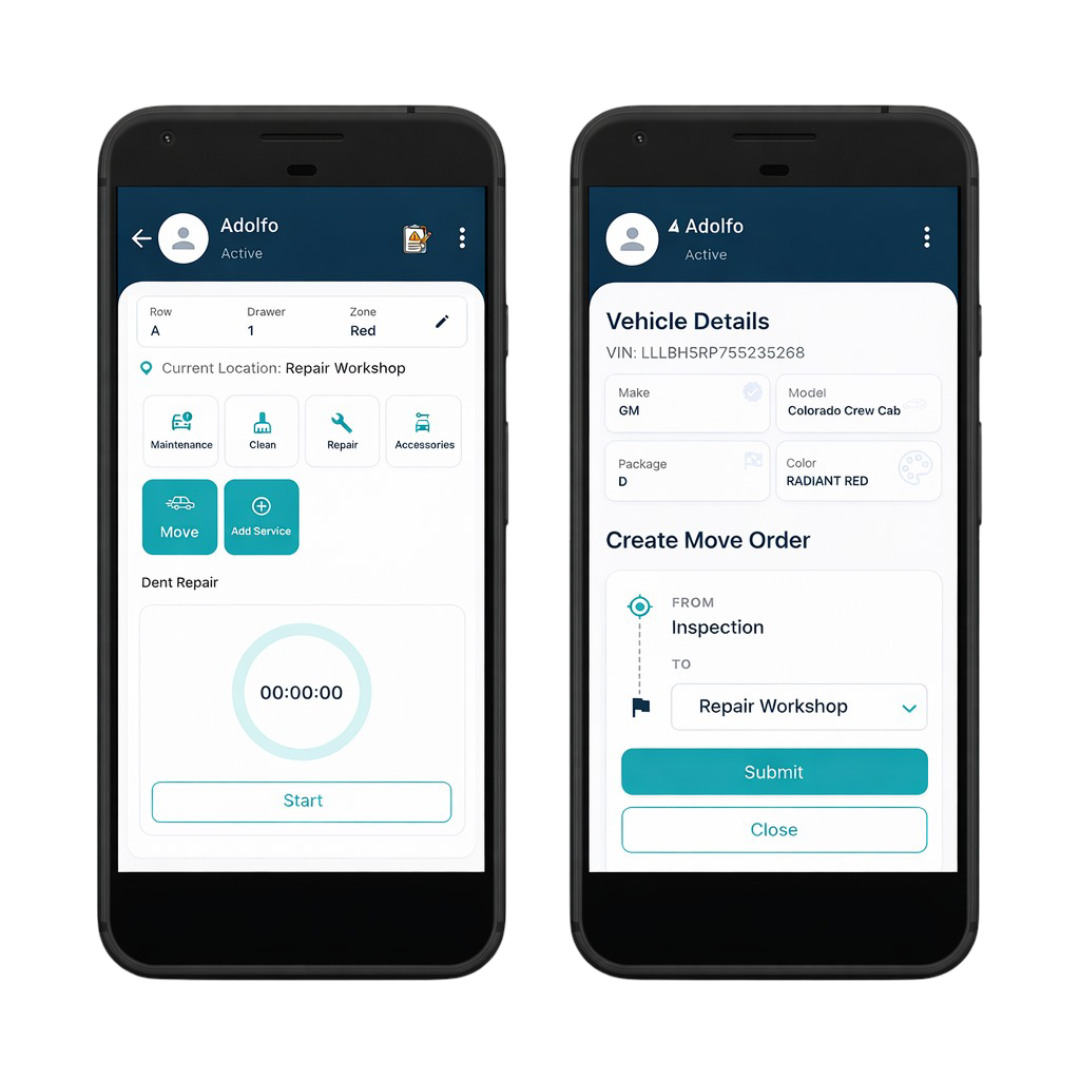

Hybrid Location Tracking Vehicles are assigned to yard zones. Movement is updated through scans and system logs rather than unreliable GPS signals.

-

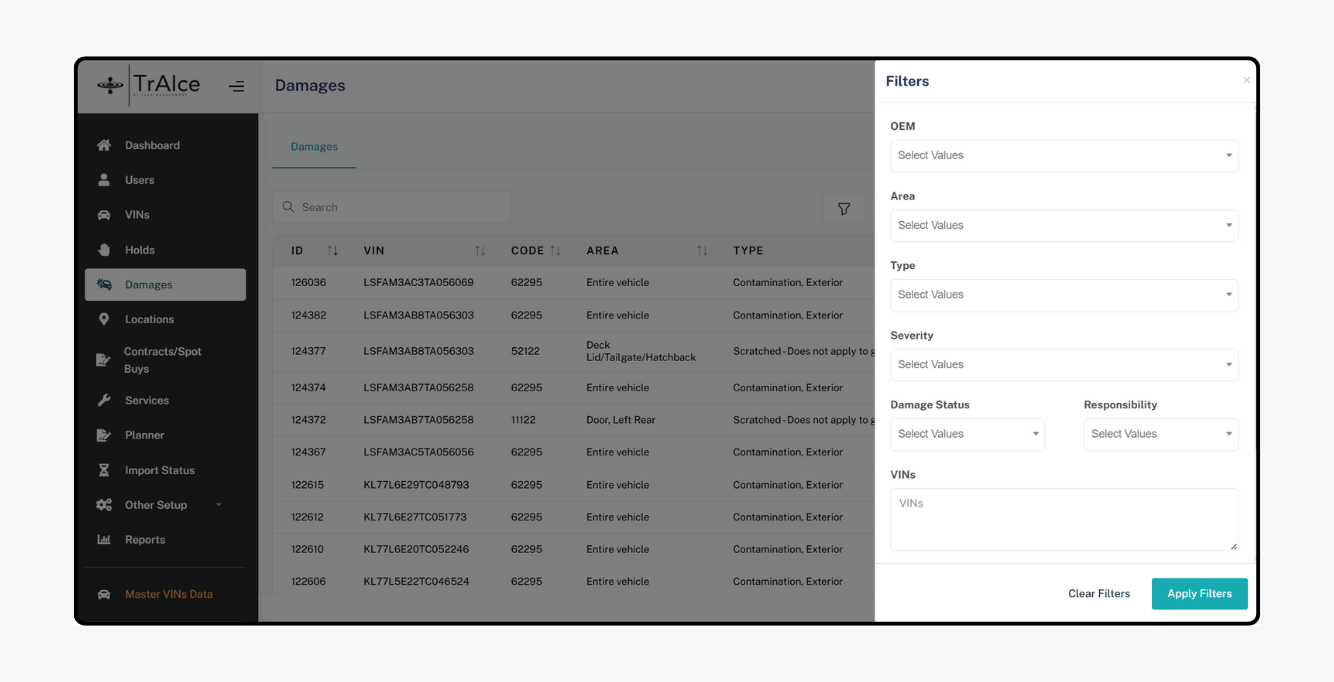

Damage Reporting Workers capture timestamped, geotagged photos of any damages directly from the app, ensuring transparency.

Web Platform & Cloud System

-

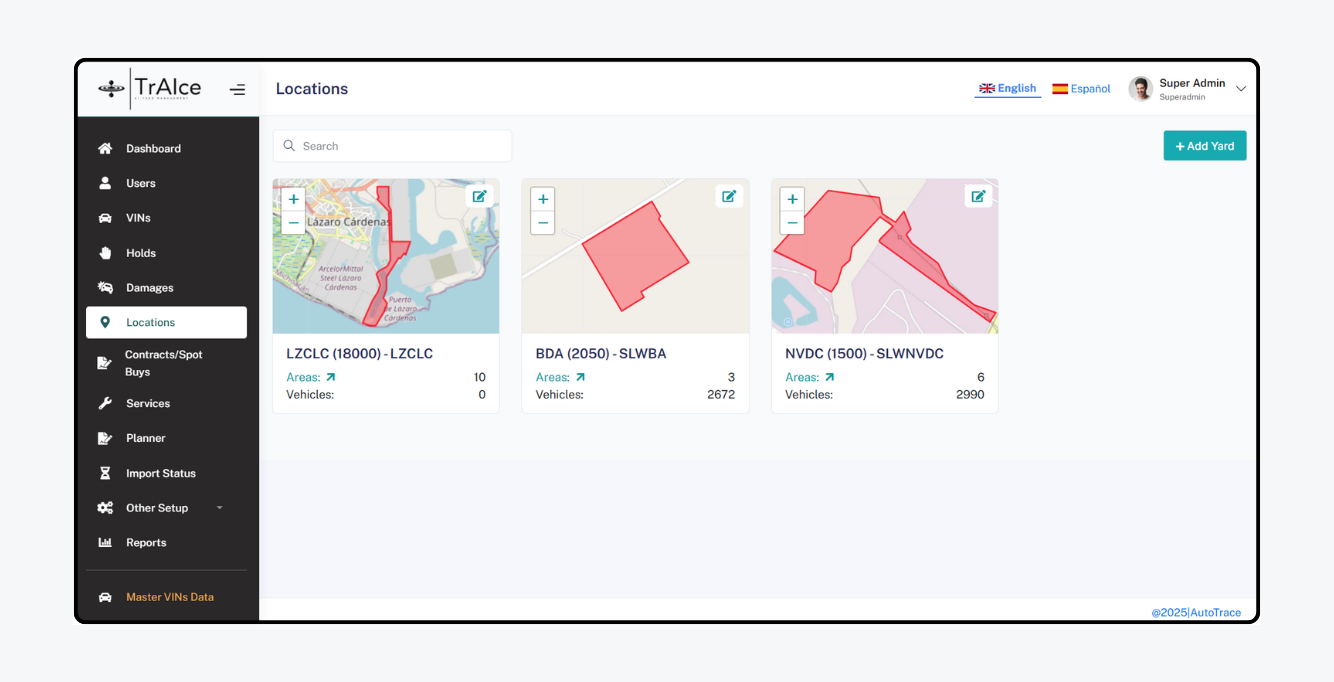

Real-Time Digital Yard Map Managers can track vehicles by zone, service status, and movement in real time.

-

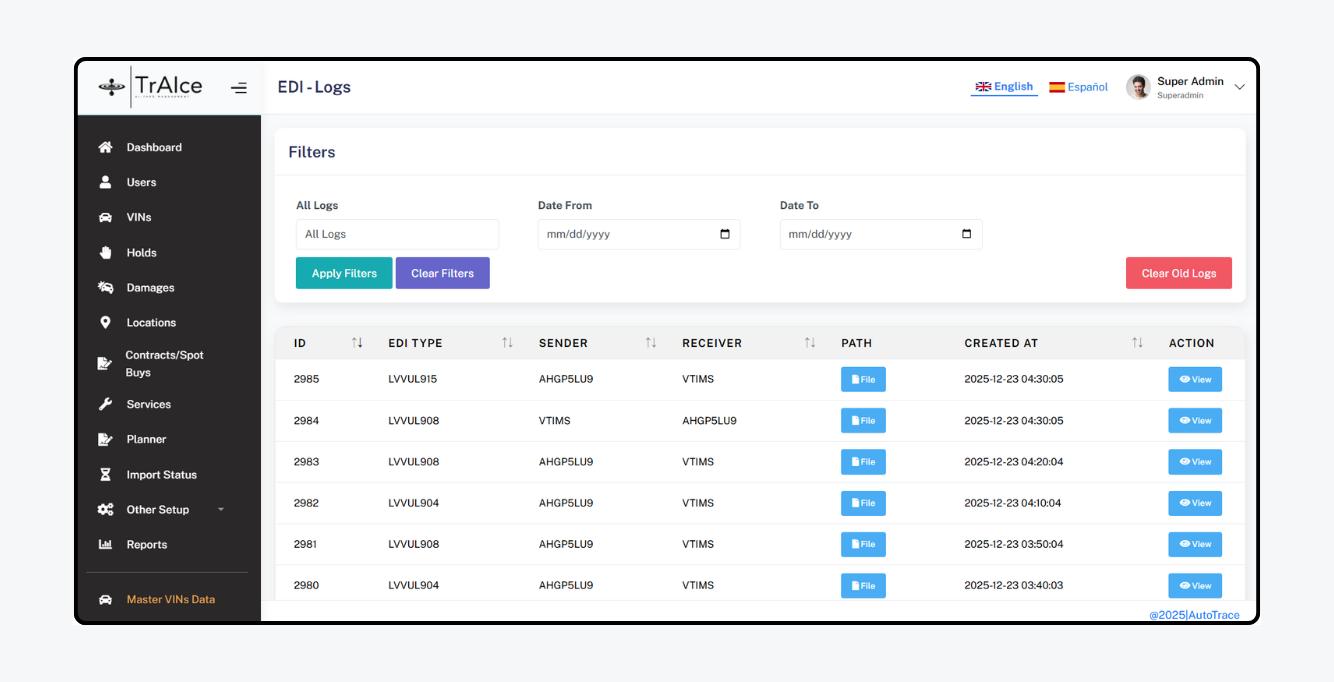

Automated Workflows via EDI Replaces manual file handling with seamless, real-time data synchronization between ACG and OEMs.

-

Centralized AWS Infrastructure API Gateway and RDS database handle VIN validation, workflows, and data sync, while S3 securely stores photos.

Product Overview

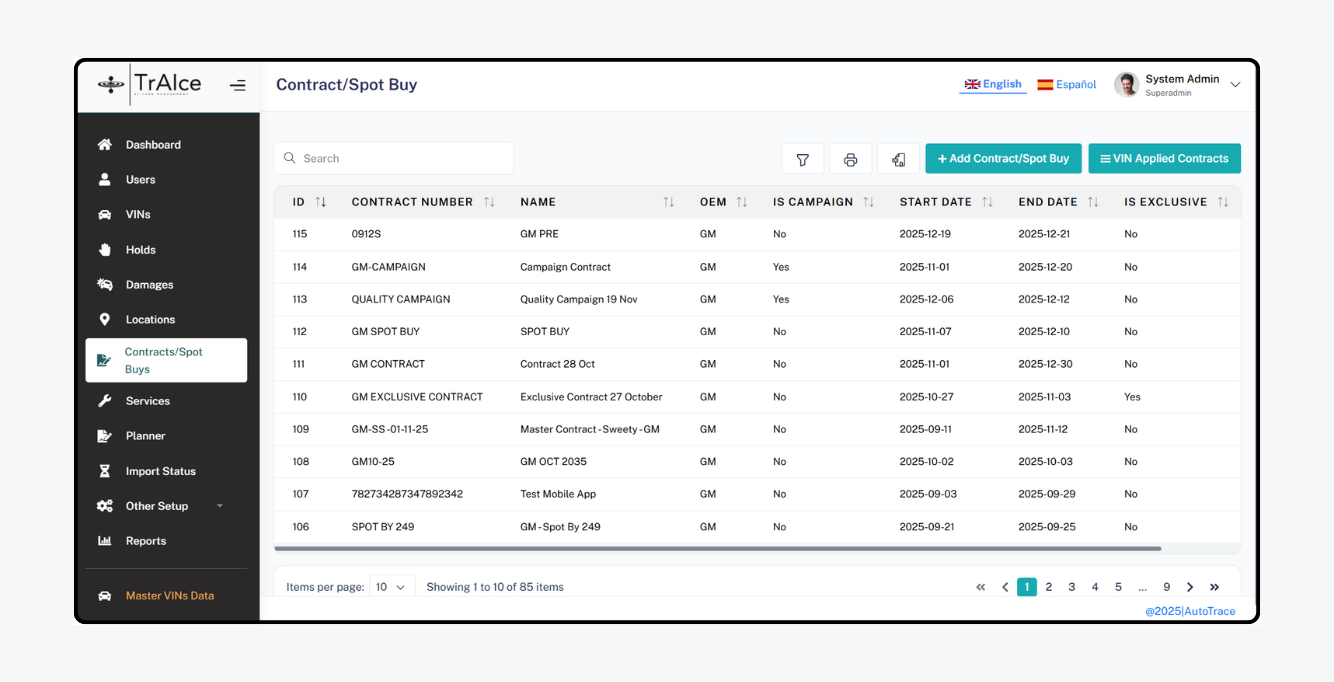

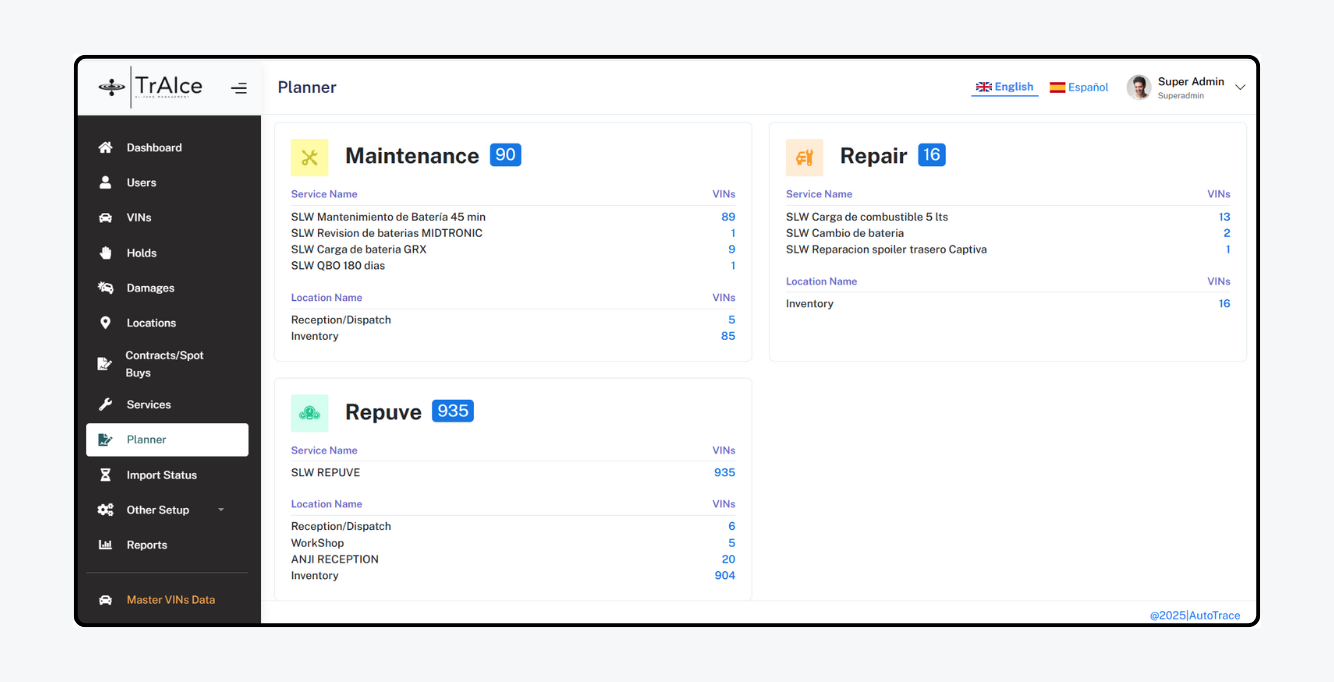

Closeloop developed a comprehensive digital yard management system combining a web portal and mobile app to modernize ACG's multi-yard operations. The platform centralizes workflows, enables real-time VIN tracking, ensures seamless OEM integration, and enforces secure, role-based access.

Technology Stack

Laravel

Laravel

Google Maps

Google Maps

Flutter

Flutter

Seamless OEM Integration

Closeloop built a robust EDI framework connecting yard operations with major OEMs like General Motors, DFY, PIBSA, and Stellantis. This integration eliminated manual uploads, enabled real-time data sync, and strengthened transparency.

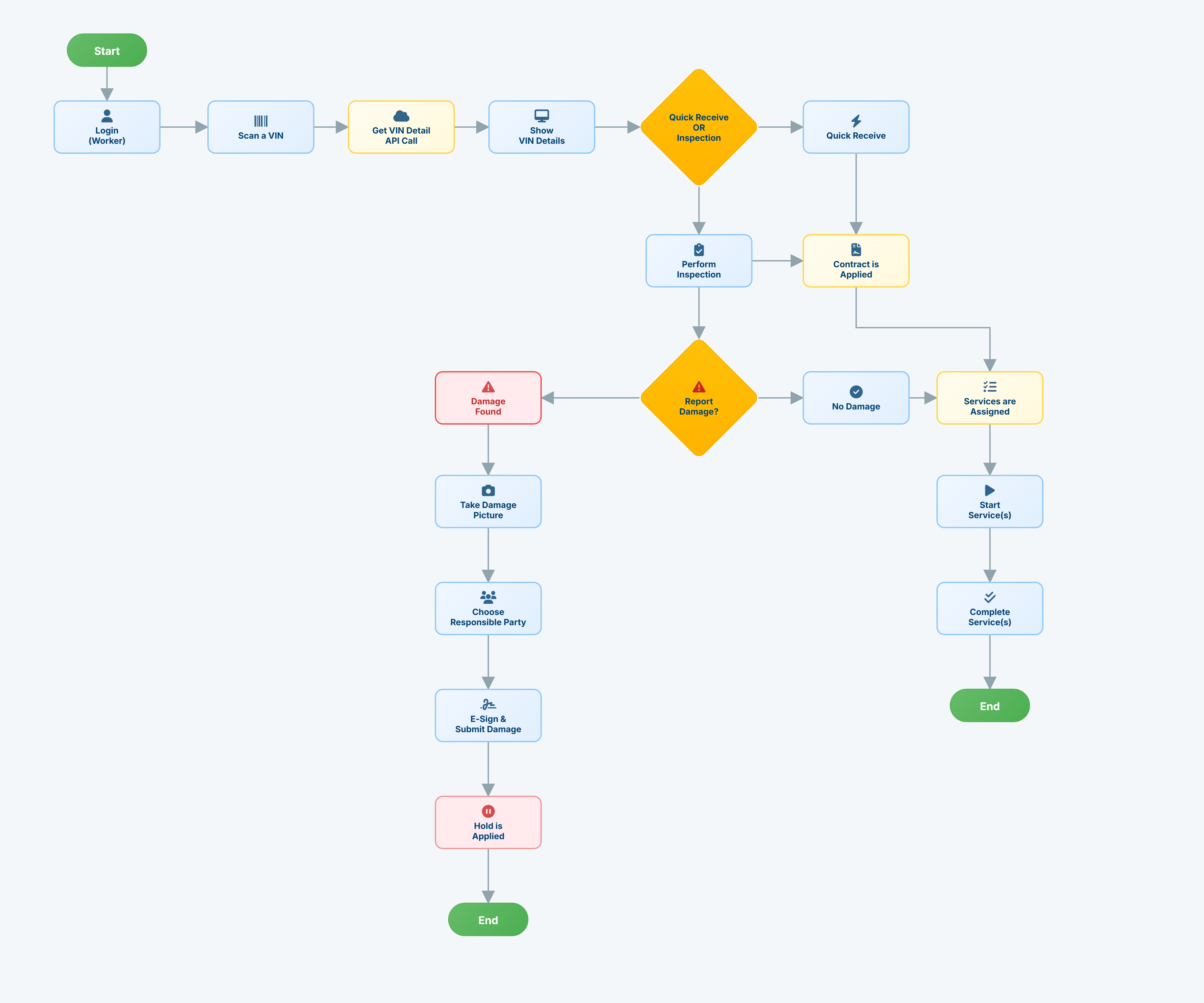

System Flow Diagram

Portfolio

These screenshots highlight the core features of the web and mobile apps, demonstrating how thoughtful design and seamless functionality come together to support real user needs.

Measurable Impact

The implementation of Closeloop's digital yard management platform delivered measurable improvements across ACG's operations.

Client Value & Feedback

Client feedback reflects not just satisfaction with technical execution but appreciation for the strategic partnership and business outcomes achieved.

"Working with Closeloop Technologies has been a transformative experience for our operations. Their team took the time to understand our challenges, collaborated closely with us throughout the process, and delivered a solution that significantly improved visibility, efficiency, and accuracy across our yards."